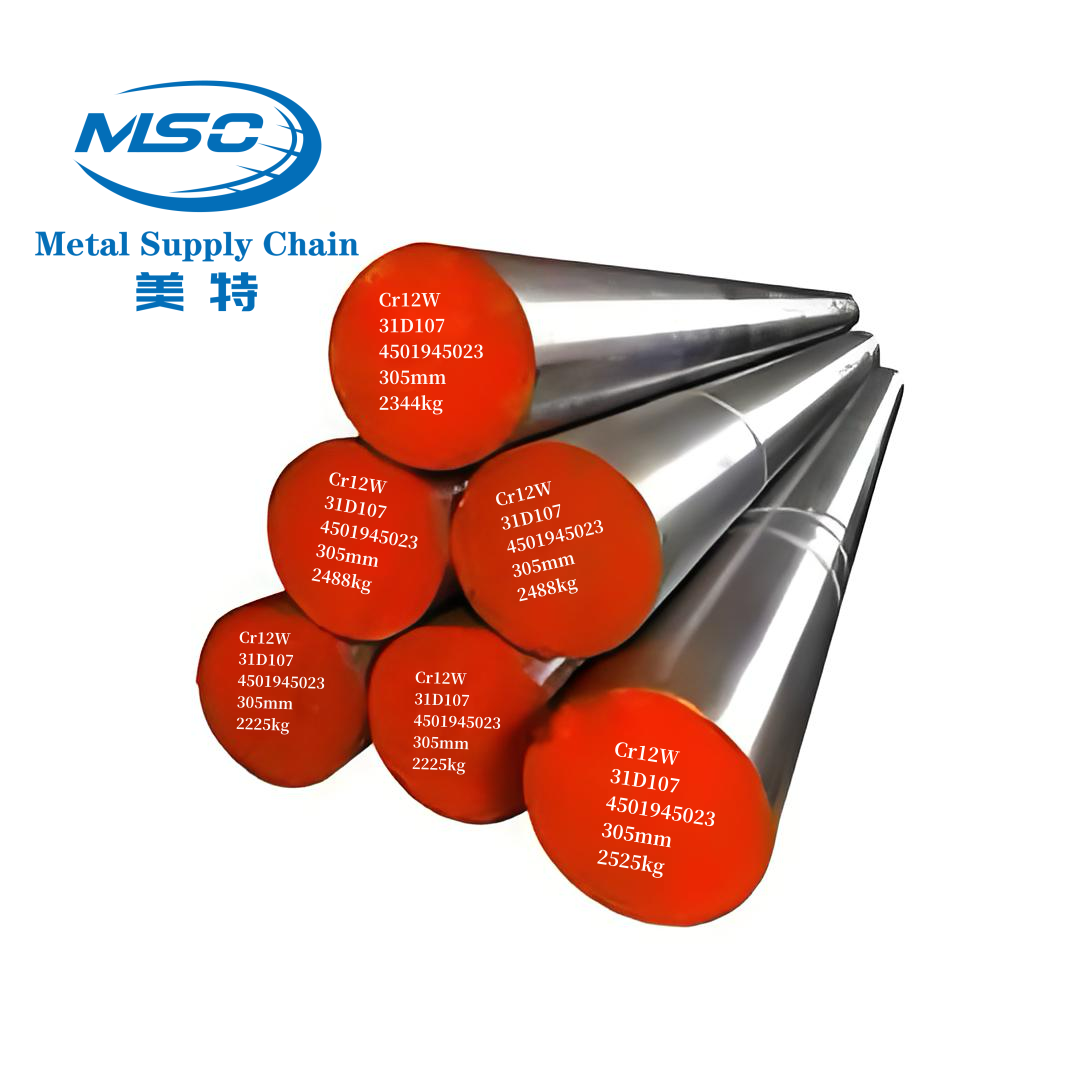

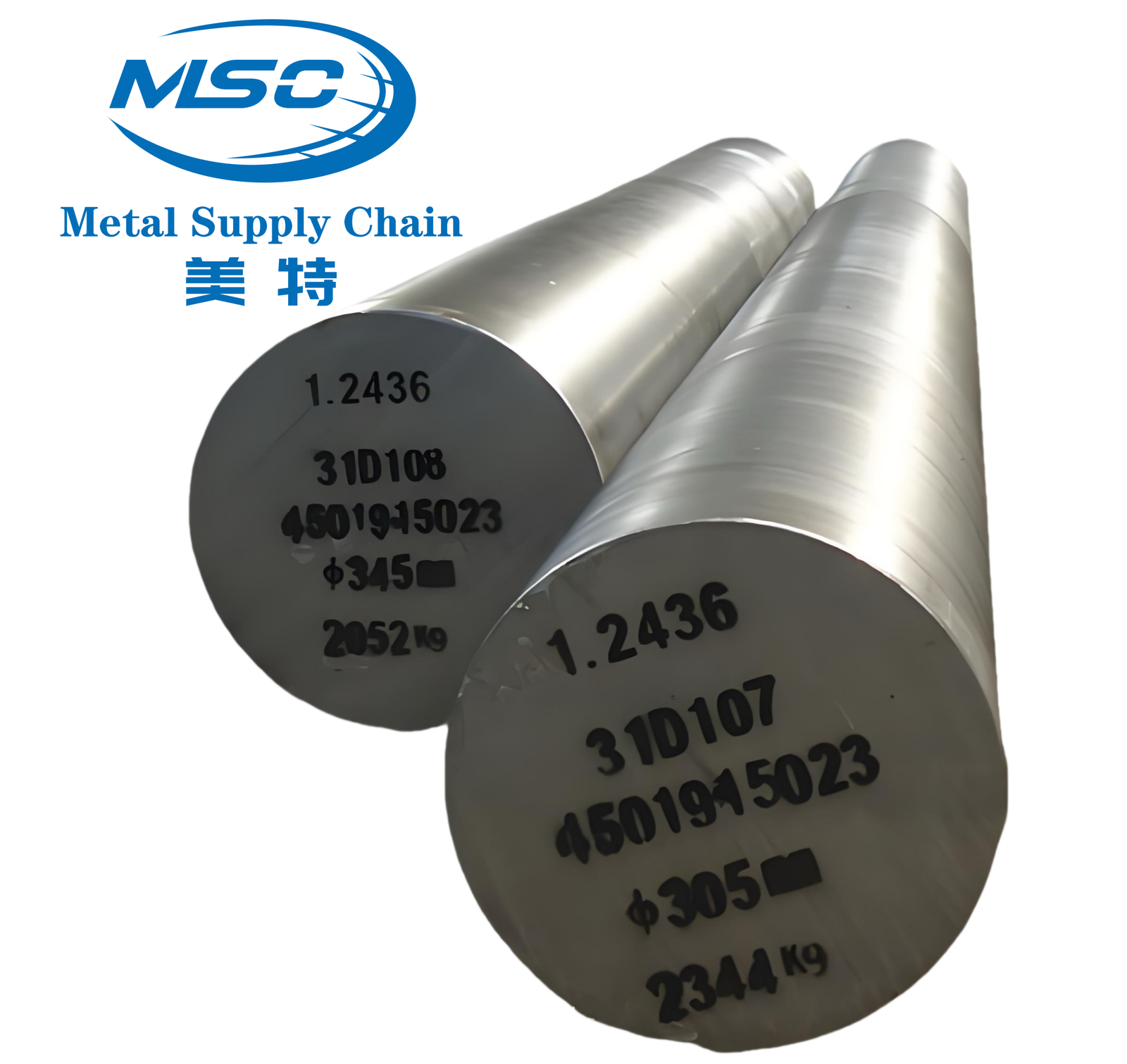

Cr12W

Similar steel grades:

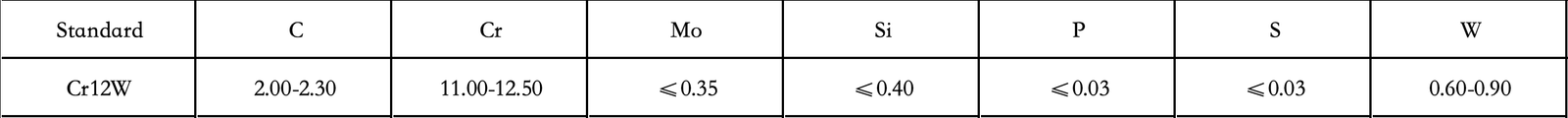

Chemical composition:

Basic Introduction:

Cr12W high wear-resistant chromium steel, high carbon, high chromium steel, cold work mold steel…. Used in the manufacture of large cross-section, complex shape, the impact of large, high wear-resistant cold work molds. Cold work molds include cold punching die, wire drawing die, stretching die, embossing die, thread rolling die, rolling plate, cold heading die and cold extrusion die. Cold work die has steel, according to its manufacture with the working conditions, should have high hardness, strength, wear resistance, adequate toughness, and high hardenability, hardenability and other process properties. Used for such purposes of alloy tool steel generally belongs to high-carbon alloy steel, carbon mass fraction of 0.80% or more, chromium is an important alloying element of such steel, its mass fraction is usually not greater than 5%. But for some of the high wear resistance requirements, quenching deformation is very small mold steel, the highest chromium mass fraction of up to 13%, and in order to form a large number of carbides, steel carbon mass fraction is also very high, up to 2.0% ~ 2.3%. Cold work die steel carbon content is high, most of its organization belongs to the over eutectic steel or leucosomal steel. Commonly used steel categories are high-carbon low-alloy steel, high-carbon high-chromium steel, chromium-molybdenum steel, medium-carbon chromium tungsten steel, etc.

Characterizations:

Cr12W high wear-resistant chromium steel, high-carbon, high-chromium Leistungen steel, cold work die steel. Containing high carbon (1.45% ~ 2.3%) and the more 12% chromium, in addition to a small amount of molybdenum and vanadium, belonging to the steel casting organization, and high-speed steel casting organization is similar to a large number of eutectic mesh in the crystalline process excitation of too much to talk about the business (of which the carbide content of 20% or so, the eutectic temperature of about 1150 ° C), these carbides are very hard, very brittle, although forging process, carbide has a certain degree of Degree of fragmentation, but the carbide along the rolling direction is banded, reticulate, block, pile distribution, the degree of segregation with the increase in steel diameter and serious.

The steel has a high degree of hardenability, hardenability, toughness, wear resistance (3 to 4 times higher than the general low alloy tool steel) and quenching volume deformation is small and so on.

Heat Treatment:

Quenching temperature 960-980℃, oil cooling. Tempering temperature 180℃±10℃

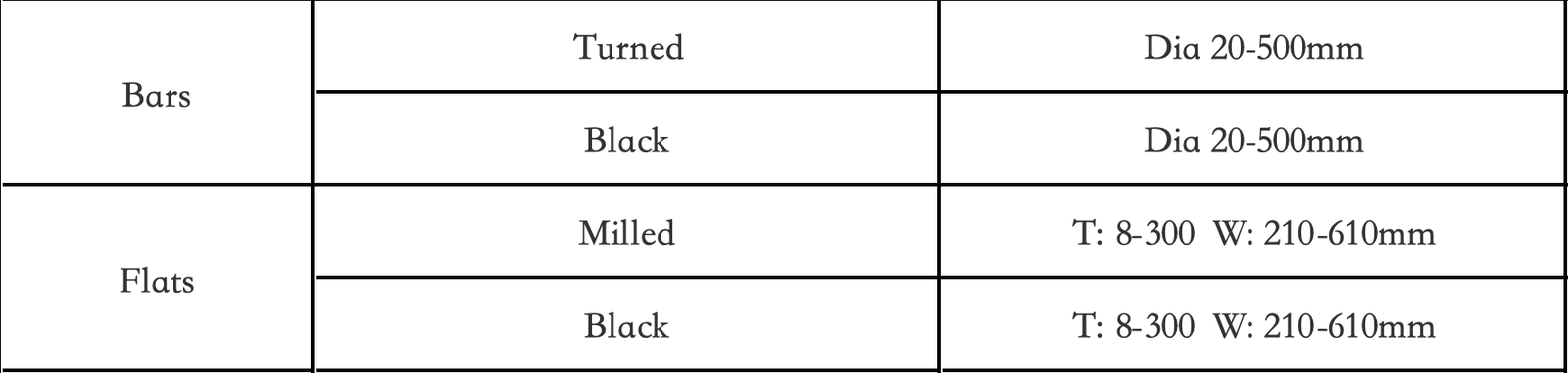

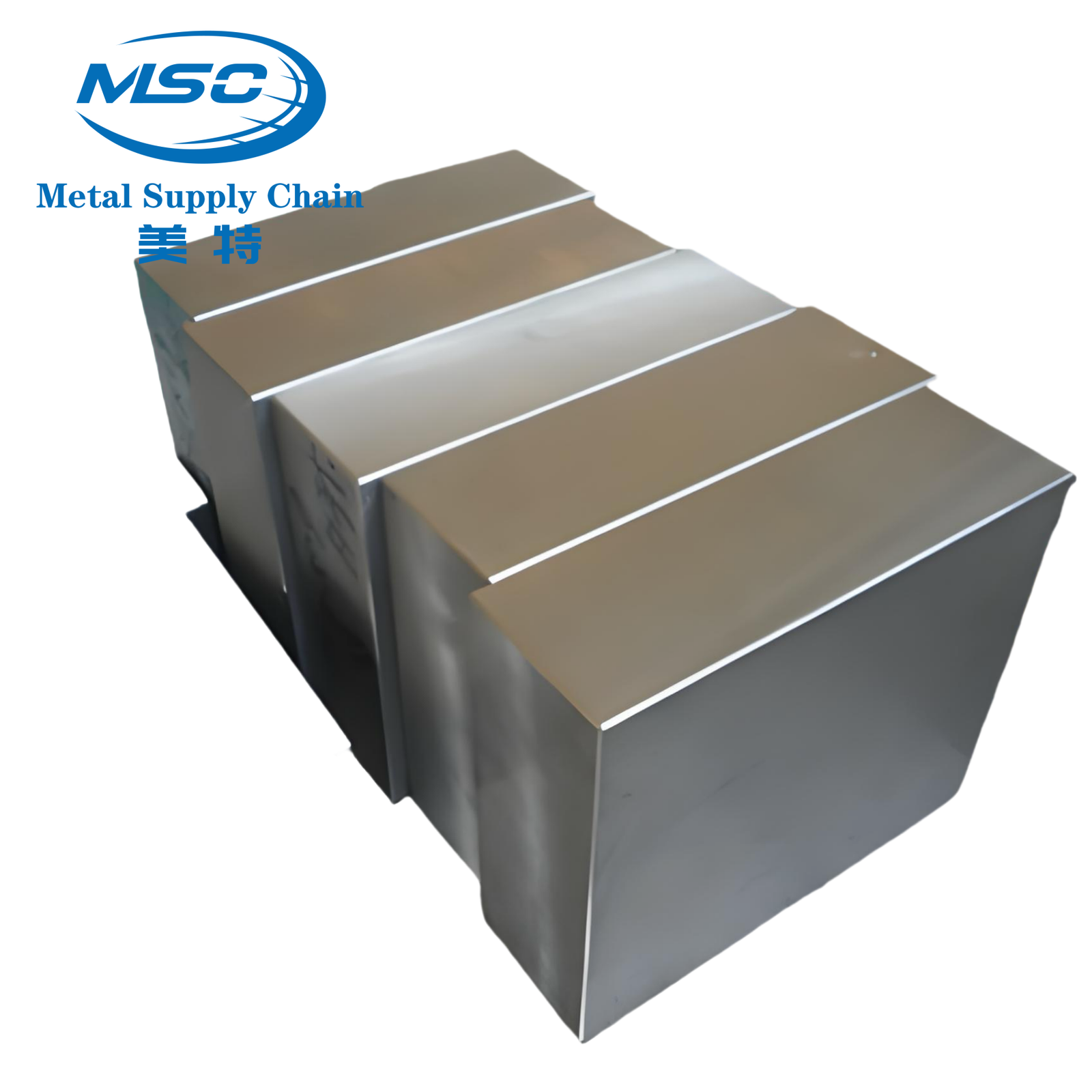

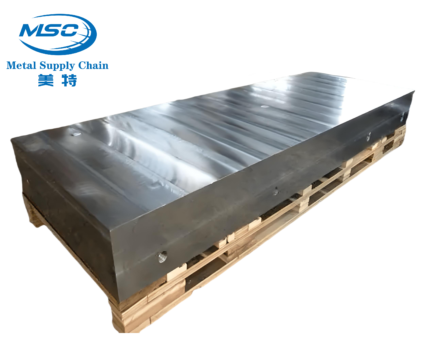

Size available: