9Cr2

Similar steel grades:

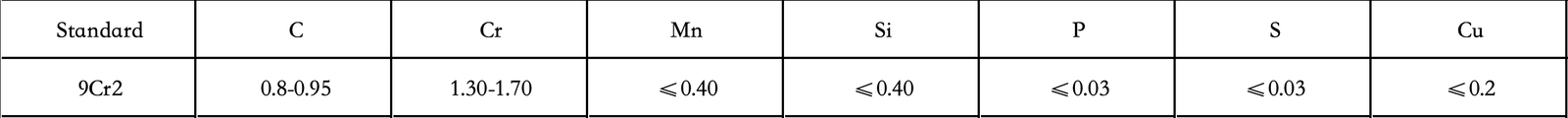

Chemical composition:

Basic Introduction:

9Cr2, performance and Cr2 equivalent, usually used in the manufacture of cold work molds, stamping die punches and concave molds, embossing dies. Hardenability is better than chromium steel, ¢ 45 ~ ¢ 50mm workpiece can be quenched in oil, high wear resistance, good tempering stability, poor machinability, heat treatment deformation is small, but the tendency to decarburization is larger, for high wear resistance, cutting is not drastic and deformation of the edge of the tool is small, such as the plate teeth, taps, drills, reamers, gear milling cutter, broach and so on, but also can be used as a cold punching die and cold rolls.

Characterizations:

(1) High hardness and wear resistance. To ensure that in long-term use will not be quickly worn, and lose its accuracy.

(2) high dimensional stability. To ensure that the gauge in the use and storage process to maintain its shape and size of the constant.

(3) Sufficient toughness. To ensure that the gauge is not used due to chance factors – collision and damage. 9Cr2 alloy tool steel.

(4) Corrosion resistance in special environments.

Heat Treatment:

Normalizing specification Fire temperature 900 ~ 920°C, hardness 302 -388HBW Batch isothermal spheroidizing annealing specification 790 ~ 810°C × 2 ~ 3h, furnace cooling, 7O0 -720°C × 3 ~ 4h, hardness ≤ 217HBW, pearlitic organization grade 2-5, reticulated carbide grade ≤ 2.

Quenching and hardening specifications (1) Quenching fire at 330-350°C, hardness 62-65HRC, fire return at 130-150°C, hardness 62-65HRC. (2) Quenching fire at 840-360°C, hardness 61-63HRC, fire return at 150-170°C, hardness 60-62HRC.

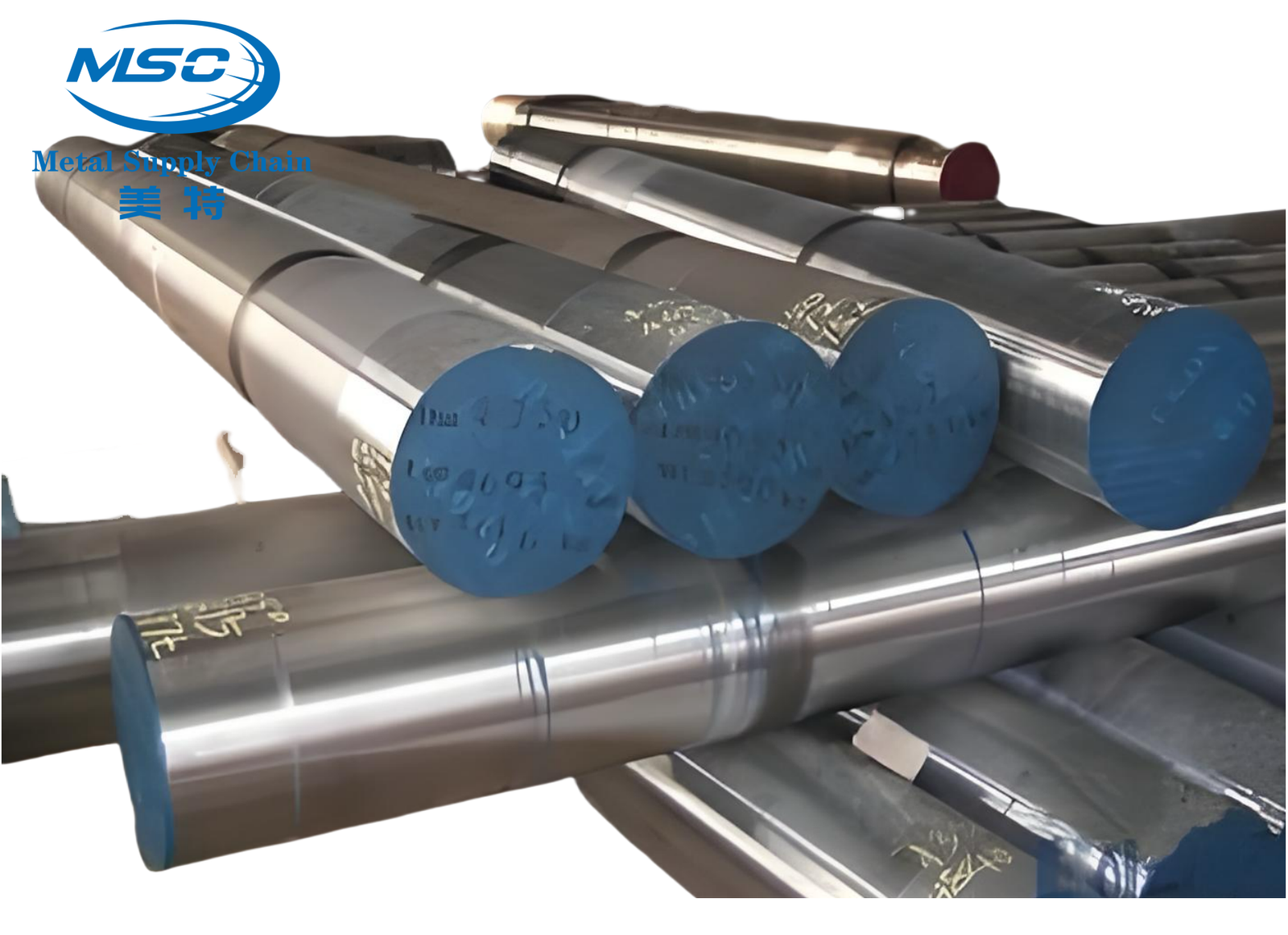

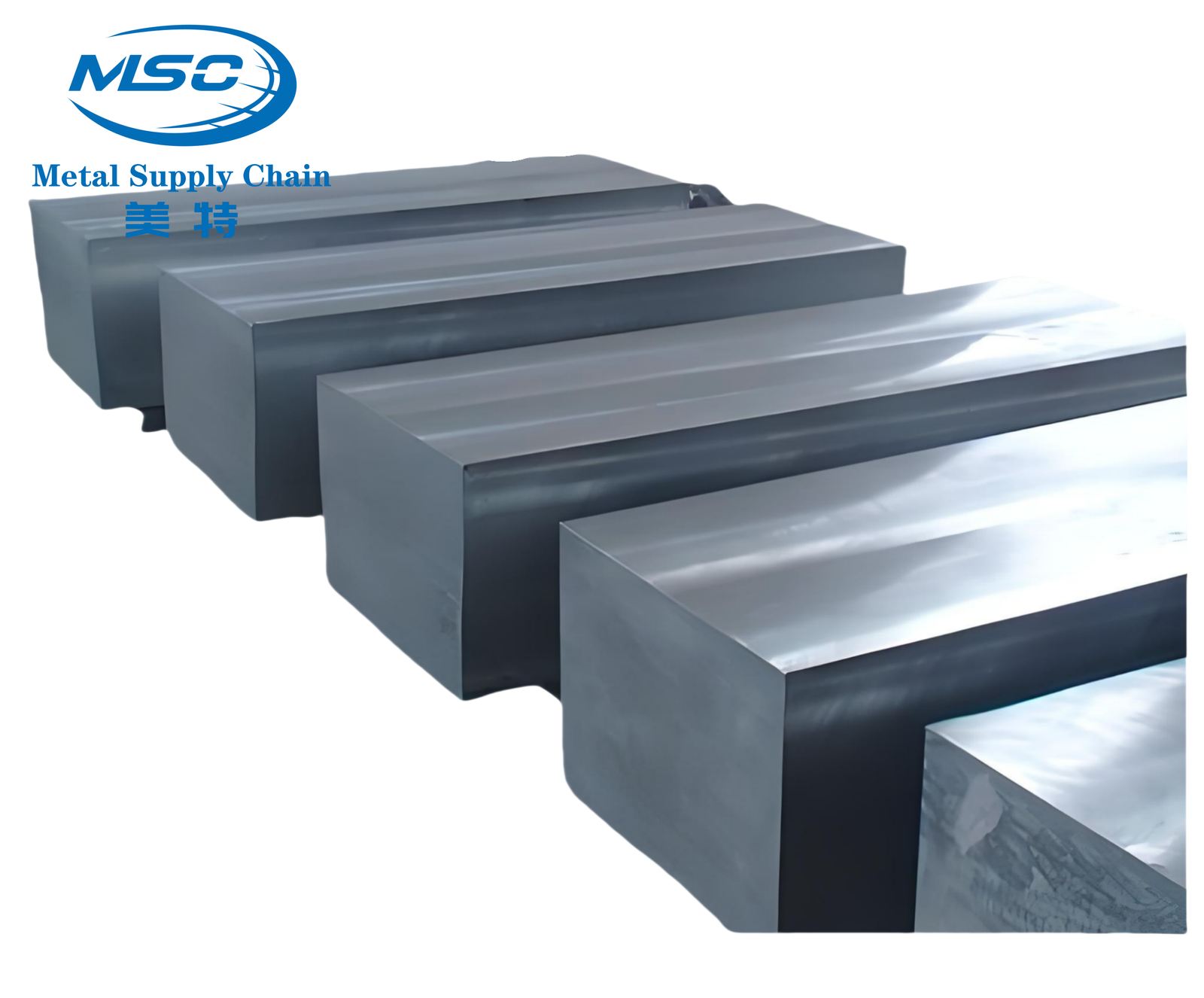

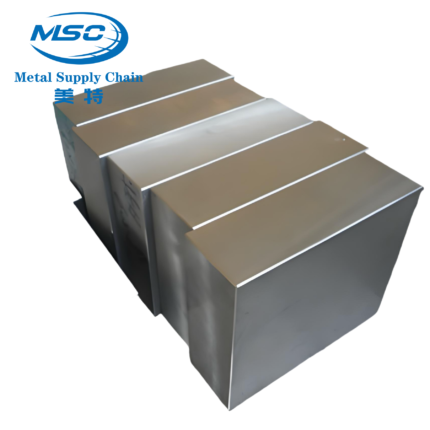

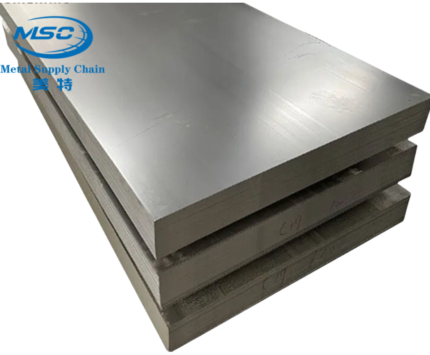

Size available: