Similar steel grades:

Basic Introduction:

5CrNiMo steel is a Chinese standard grade, is a high endurance hammer hammer mold steel, has good heat resistance, strength and high wear resistance. The steel compared with 5CrMnMo steel, high temperature strength, heat resistance and heat fatigue resistance performance is comparable, in the present and 500 ~ 600 ℃ when the mechanical properties are almost the same. When heated to 500 ℃, can still maintain a hardness of about 300HBW. As the steel contains molybdenum, it is not sensitive to temper brittleness. After cooling slowly from 600 ℃, the impact properties 300mmx400mmx300mm large workpiece, by 820 ℃ oil quenching and tempering at 560 ℃, the section hardness of each part is almost the same. However, such steel is prone to the formation of white spots, the need for strict control of the refining process and the optimal cooling system after forging and rolling.

Isothermal temperature of 650 ~ 680 ℃. Normalizing can refine the metallographic organization and improve mechanical properties. High-temperature tempering reduces the thickness of steel for medium and large hot forging die (thickness) high-temperature tempering softening process can be

As a small hot work die forging billet (thickness <300mm), as well as the old die regeneration before the softening process.

Characterizations:

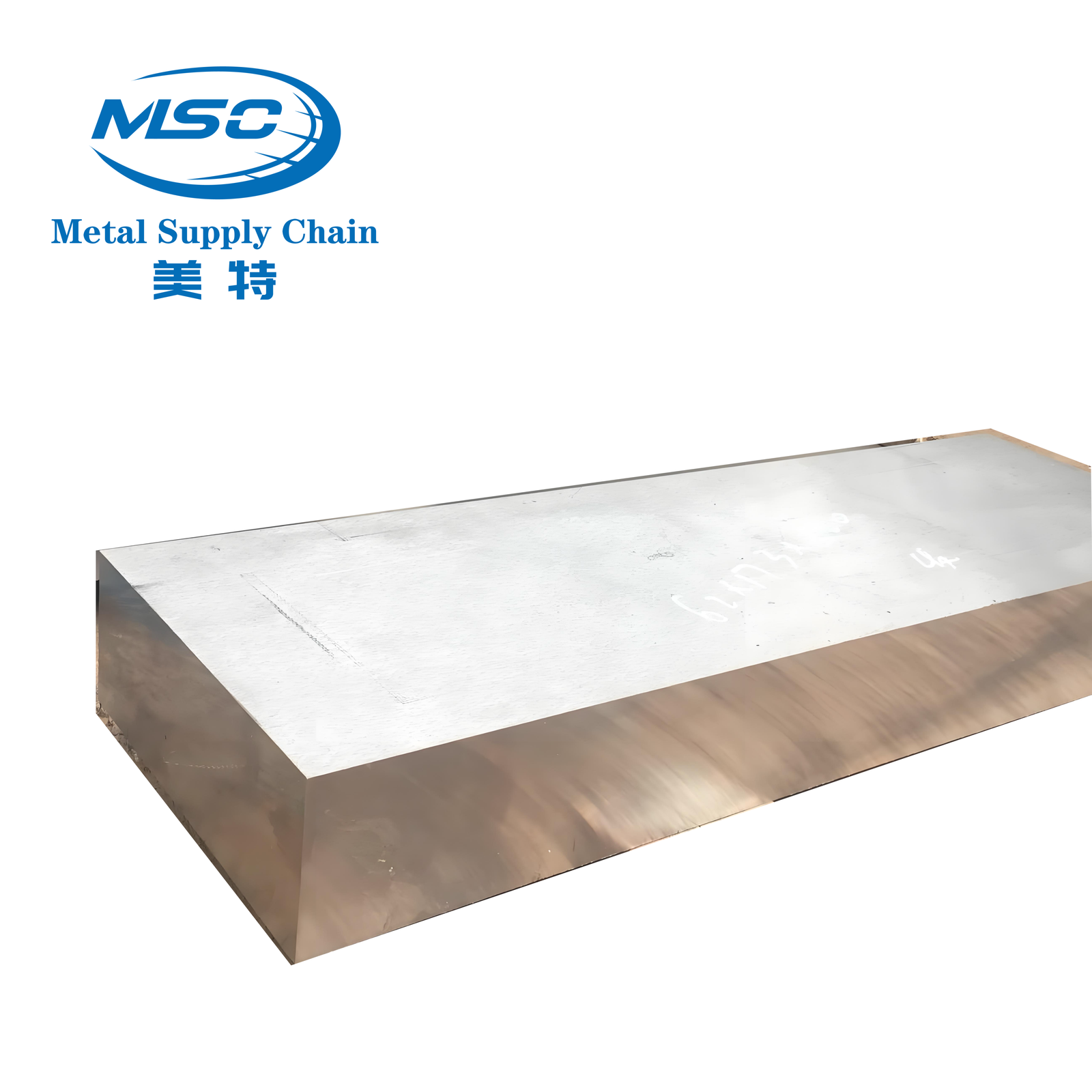

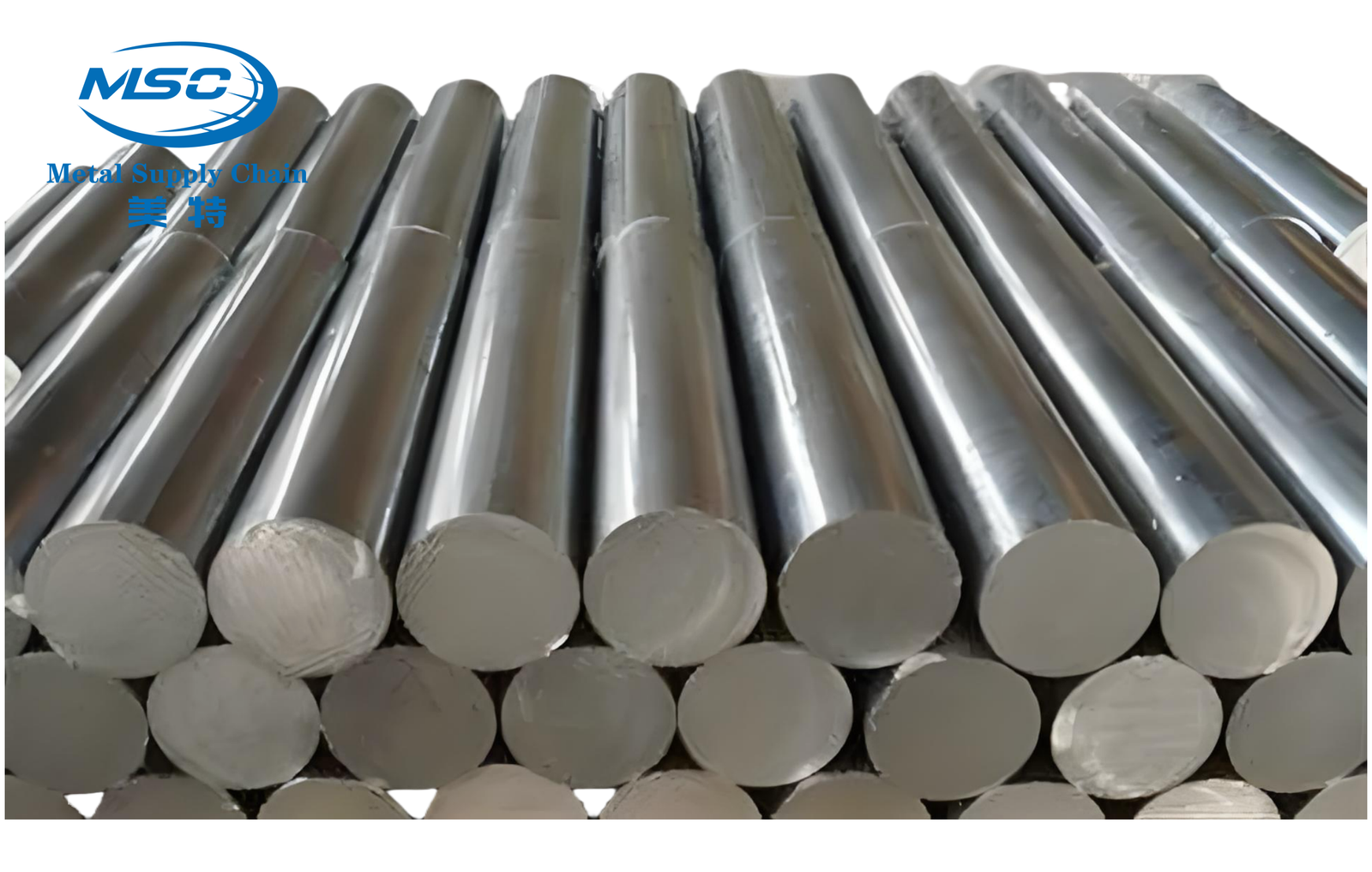

Suitable for the manufacture of a variety of complex shapes, large impact zinc, working temperature is not too high, edge length > 400mm medium and large hammer forging die and cutting edge die. Simple shape manufacturing using general manufacturing process smelting vacuum refining process to ensure the cleanliness of the steel; the use of the best large-scale professional heat treatment, so that the batch to obtain pre-slicing effect, slicing uniformity.

Chemical Composition:

Heat treatment:

Heat treatment:

1. Large mold quenching heating temperature using the upper limit, small molds (side length 200 ~ 300mm or less) using the lower limit;

2. In order to avoid forging hammer mold quenching produce more violent and tension, from 830 ~ 860 ℃ heating, first pre-cooled in the air heating to 750 ~ 780 ℃, oil cooling to 150 ~ 180 ℃, take out and cool. Adjustment and;

3. For large molds should be placed 600 ~ 650 ℃ preheating furnace, through the furnace and then immediately dissipate the heat; in order to heat the effect is better, the mold should be placed on a high 60 ~ 100mm mat heating.

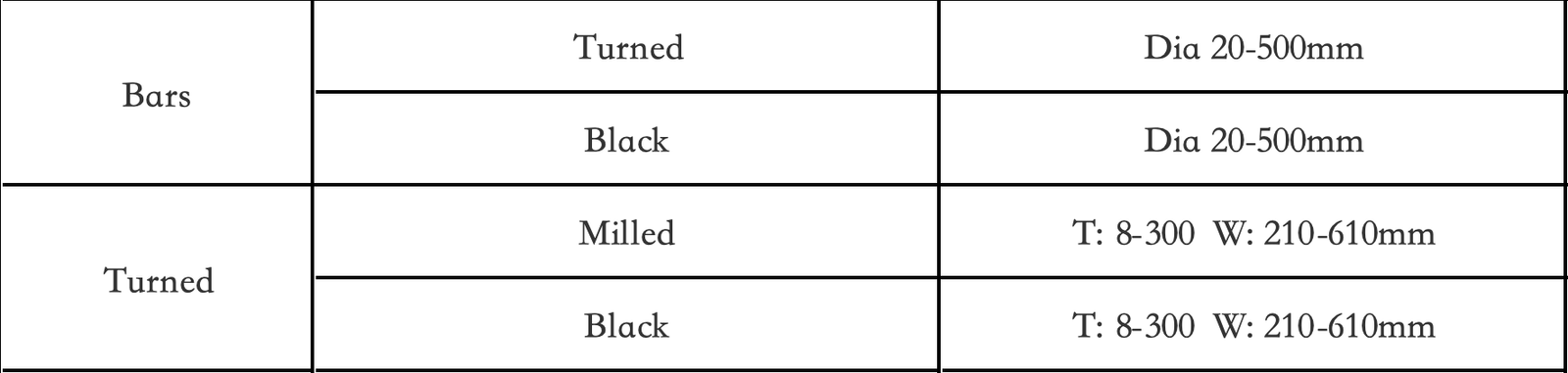

Available sizes: