Similar steel grades:

Basic introduction:

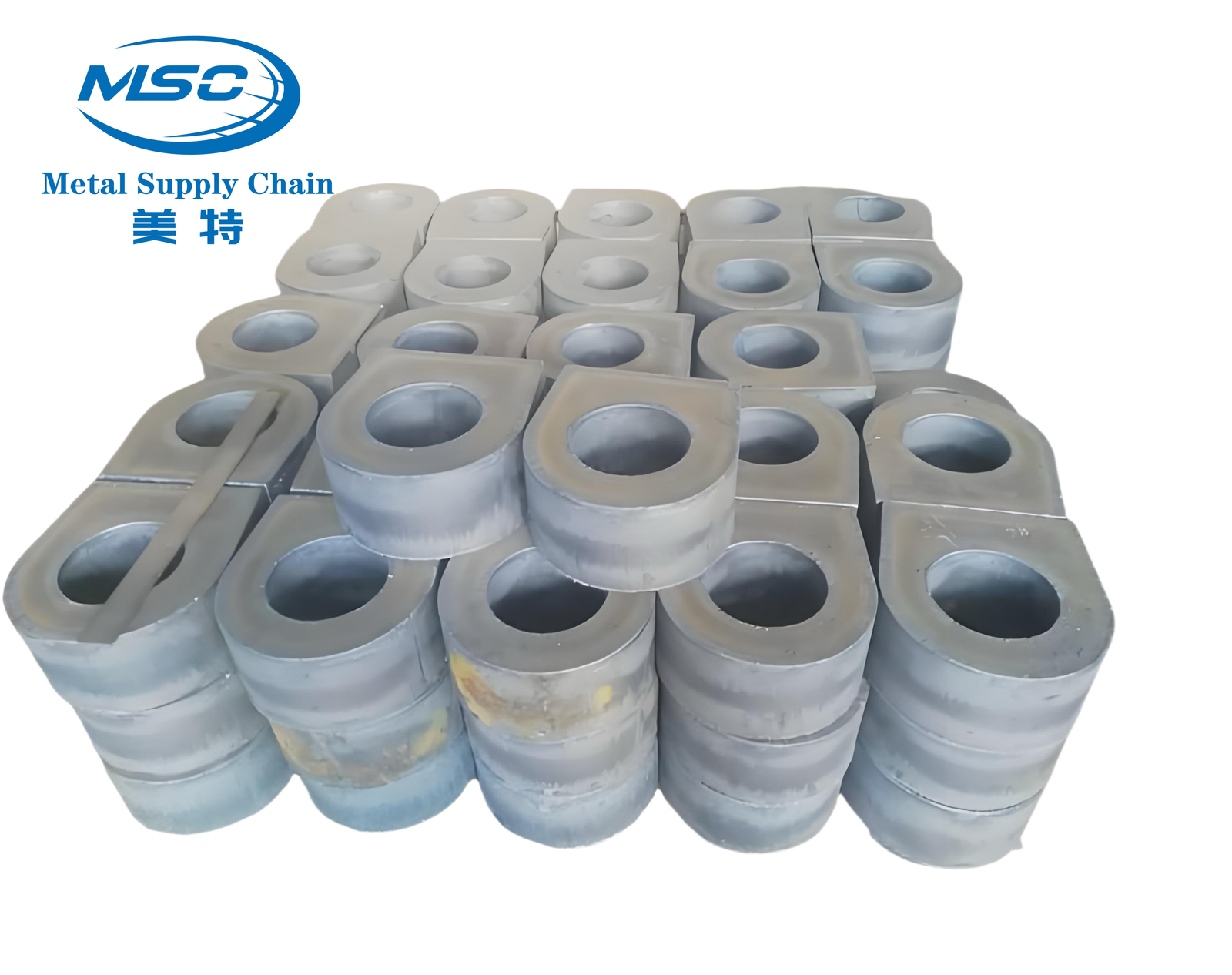

When using 4Cr5WMoSiV steel, it can replace 5CrMnMo steel and significantly improve the forging heat strength of the mold. When applied to large arc shear edge, such as the size of 1720mm x 147mm x 5mm or 1700mm x 177mm x 90.25mm shear edge, the service life of the die can be increased from less than 200 pieces to about 1000 pieces.

4Cr5WMoSiV steel can be quenched by air cooling, has low superheat sensitivity, after quenching and tempering can show secondary hardening phenomenon, and at the same time, has good oxidation resistance and thermal fatigue resistance.

Characteristics:

Can be used to shear the shear blade of hot rolled plate. By grinding the failed shear blade and laser quenching and repairing the edge, the service life of the repaired shear blade can still reach or even exceed that of the new shear blade.

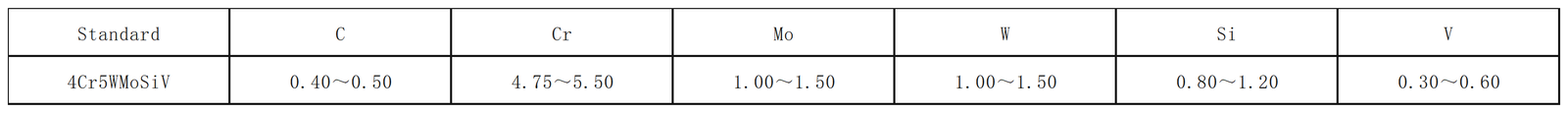

Chemical composition:

Heat treatment:

1. Molding temperature: 900℃~1100℃.

2. Annealing temperature: 800℃~840℃;

3. Quenching temperature: 1000 ℃ ~ 1050 ℃

4. Tempering temperature: 500℃~530℃.

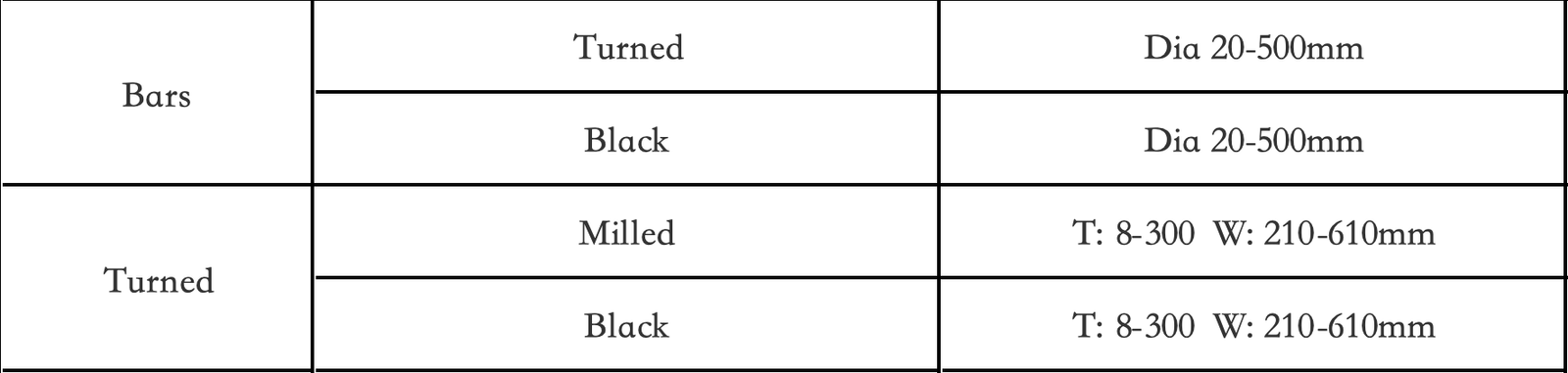

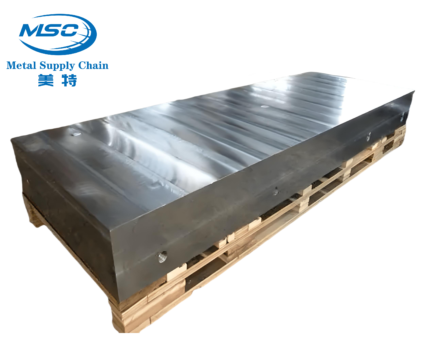

Available sizes: