Similar steel grades:

Chemical composition:

Basic Introduction:

DC53 steel ingot this steel has a general low carbon steel inherent in the excellent cold formability and weldability, heat treatment tendency to decarburization and quenching deformation are small, fully quenched in oil up to 12 ~ 18mm in diameter (> 95 ℃ martensite); in the static load, fatigue and multiple impact loads, its notch sensitivity and overload sensitivity are low. This steel as a low carbon martensite quenching steel, in the quenching and low temperature tempering, not only has a combination of high strength and good plasticity, toughness, but also has a low cold brittle transition

Characterizations:

(1) Used for blanking dies, cold forming dies, cold drawing dies, forming rolled silver punches, cold extrusion dies.

(2) Precision blanking and stamping dies for various purposes of wire-cutting processing.

(3) Used for difficult-to-machine materials, such as cold forging, deep drawing and thread rolling dies, high-speed blanking punches, stainless steel plate punches.

(4) It is suitable for cold stamping dies with high wear resistance, high hardness and high toughness.

(5) Used especially for the working condition requirements than D2 steel molds and molds with high toughness requirements, outstanding cost performance.

(6) Can be used for large molds and precision molds.

Heat Treatment:

Quenching temperature: 940~960℃

Tempering temperature: 180~220℃

Hardness: 60~62HRC

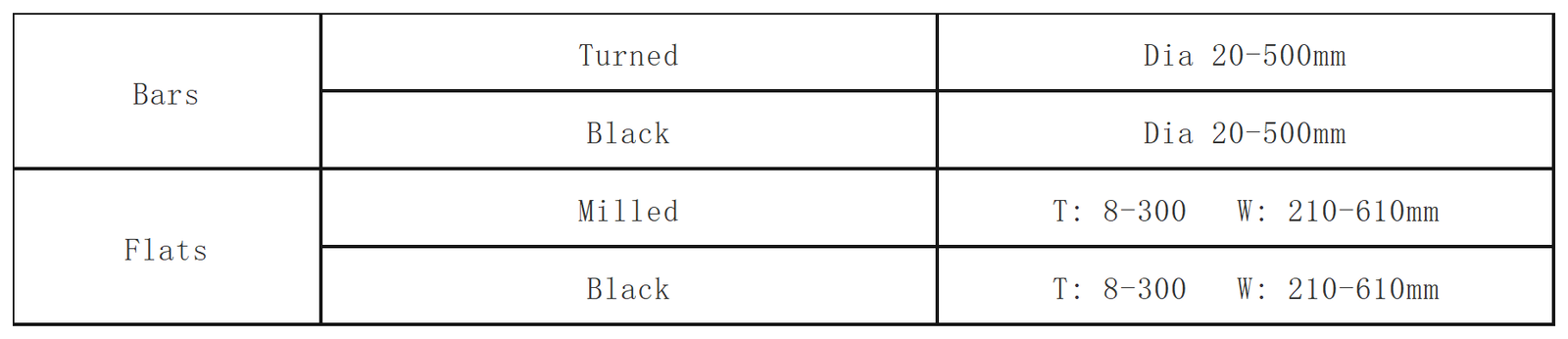

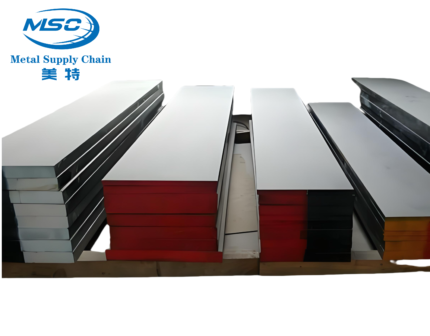

Size available: