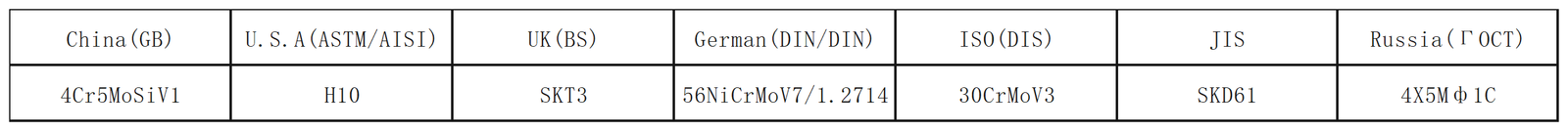

Similar steel grades:

Basic Introduction:

H10 steel is an American AISI/ASTM standard hot work mold steel. The steel has high chromium content, high hardenability, quenching air cooling can be obtained martensitic organization. Carbon content is low in carbon to ensure that the steel quenched, tempered toughness, while making the steel has good thermal conductivity and high impact toughness; high temperature tempering produces a secondary hardening, in order to obtain a high resistance to tempering at the same time, it can improve wear resistance, resistance to hot labor, oxidation resistance and impact toughness.

The steel after quenching and tempering treatment, the comprehensive performance is good, the organization is uniform and dense, wear resistance and thermal fatigue resistance is high, small deformation. However, if the surface of the steel appears poor carbon layer, even if the thickness of the decarburized layer is very thin, but also bright point damage to the fatigue resistance of the die steel. Quenching temperature 830 ~ 870 C. The steel in the 600C or so comprehensive performance is good, thermal deformation rate is low, its performance and service life is higher than 3Cr2W8V steel.

Characteristics:

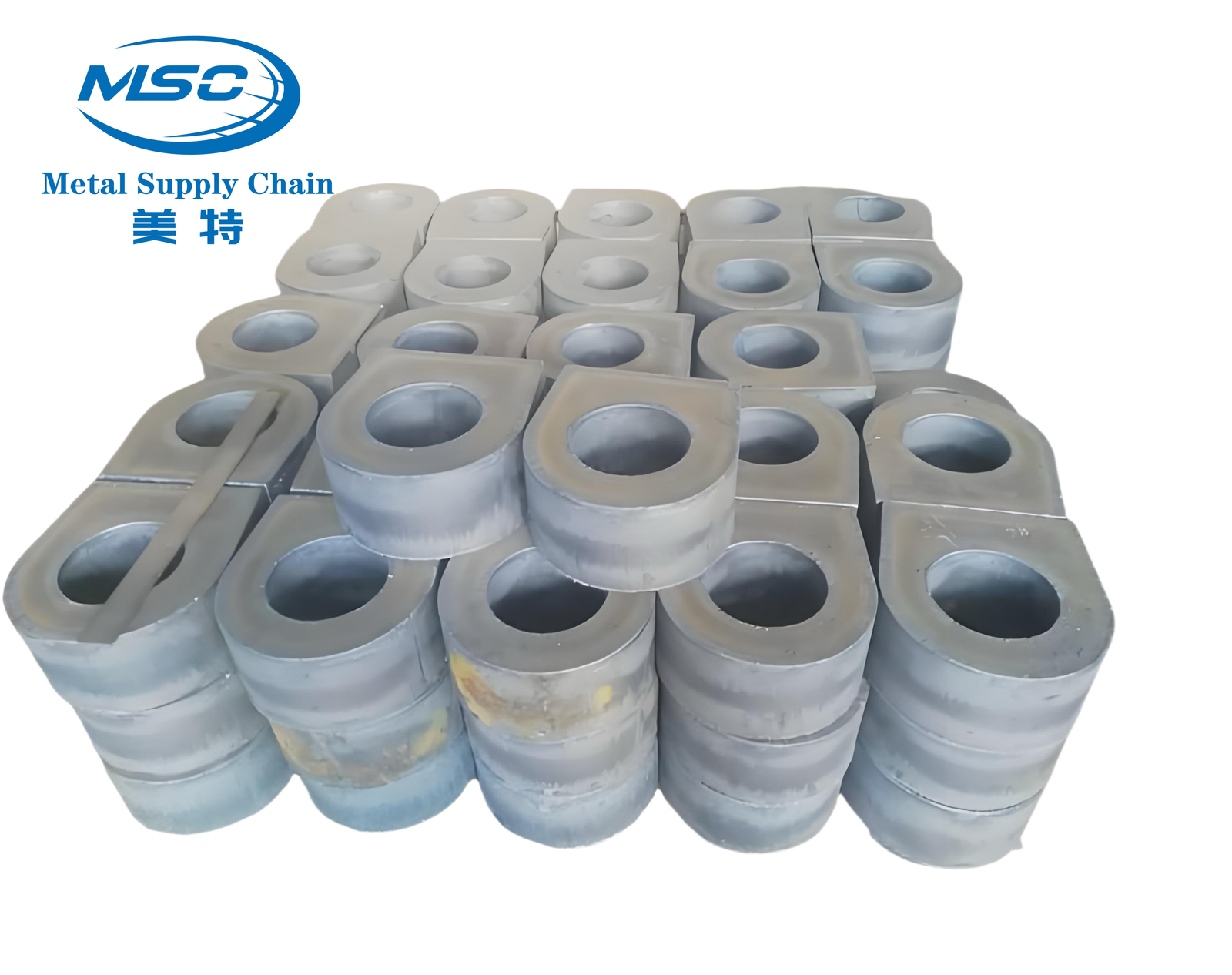

Suitable for making large die casting molds, extrusion tools, support tools, mold holders, large molds applied to plastics treated with hot matter plasticity, press shafts, grommets.

Chemical composition:

Heat treatment:

1. Heat between 980 and 1050°C.

2. Holding time depends on the size of the material and the depth of the required hardness, about 30 minutes to 2 hours.

3. Quenching and cooling is used, which can effectively increase the hardness and toughness of the steel.

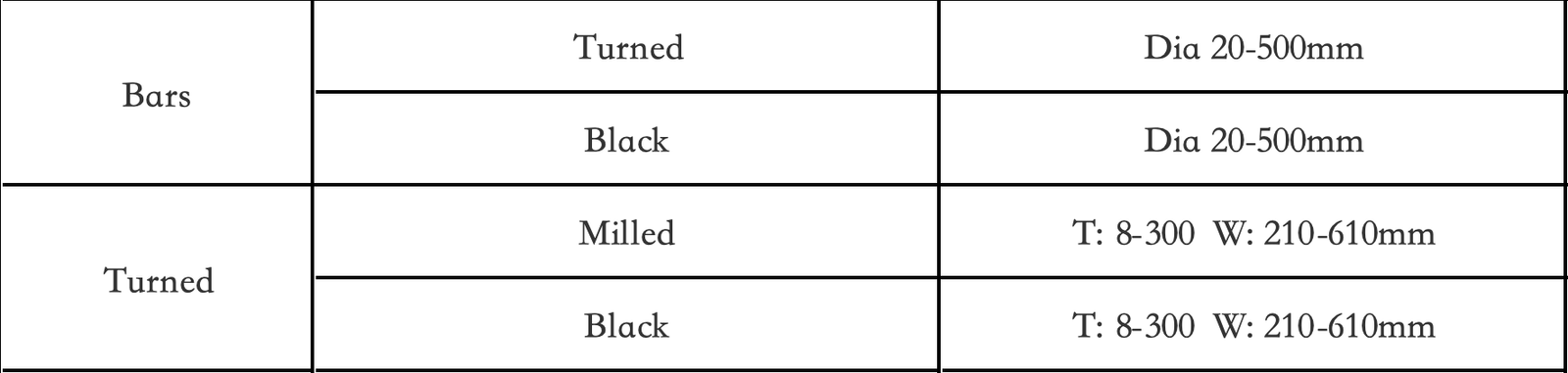

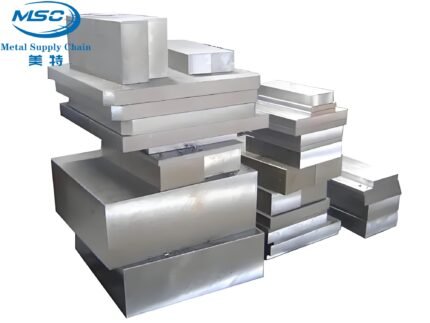

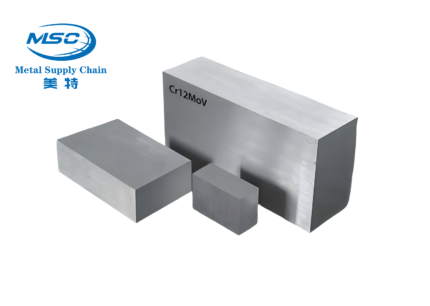

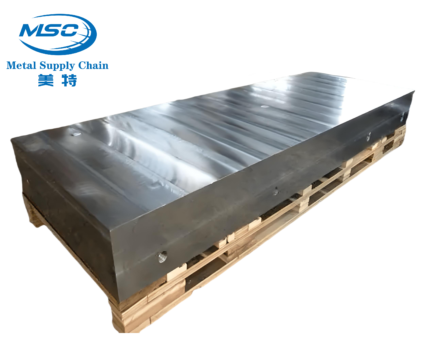

Available sizes: