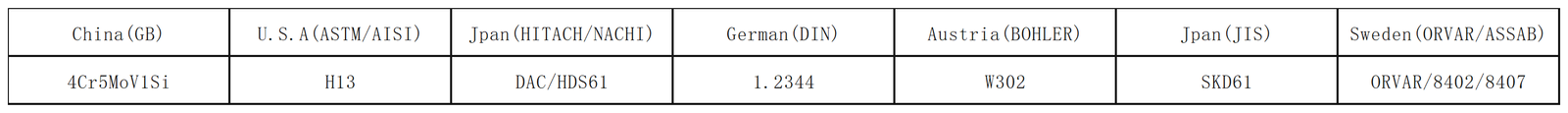

Similar steel grades:

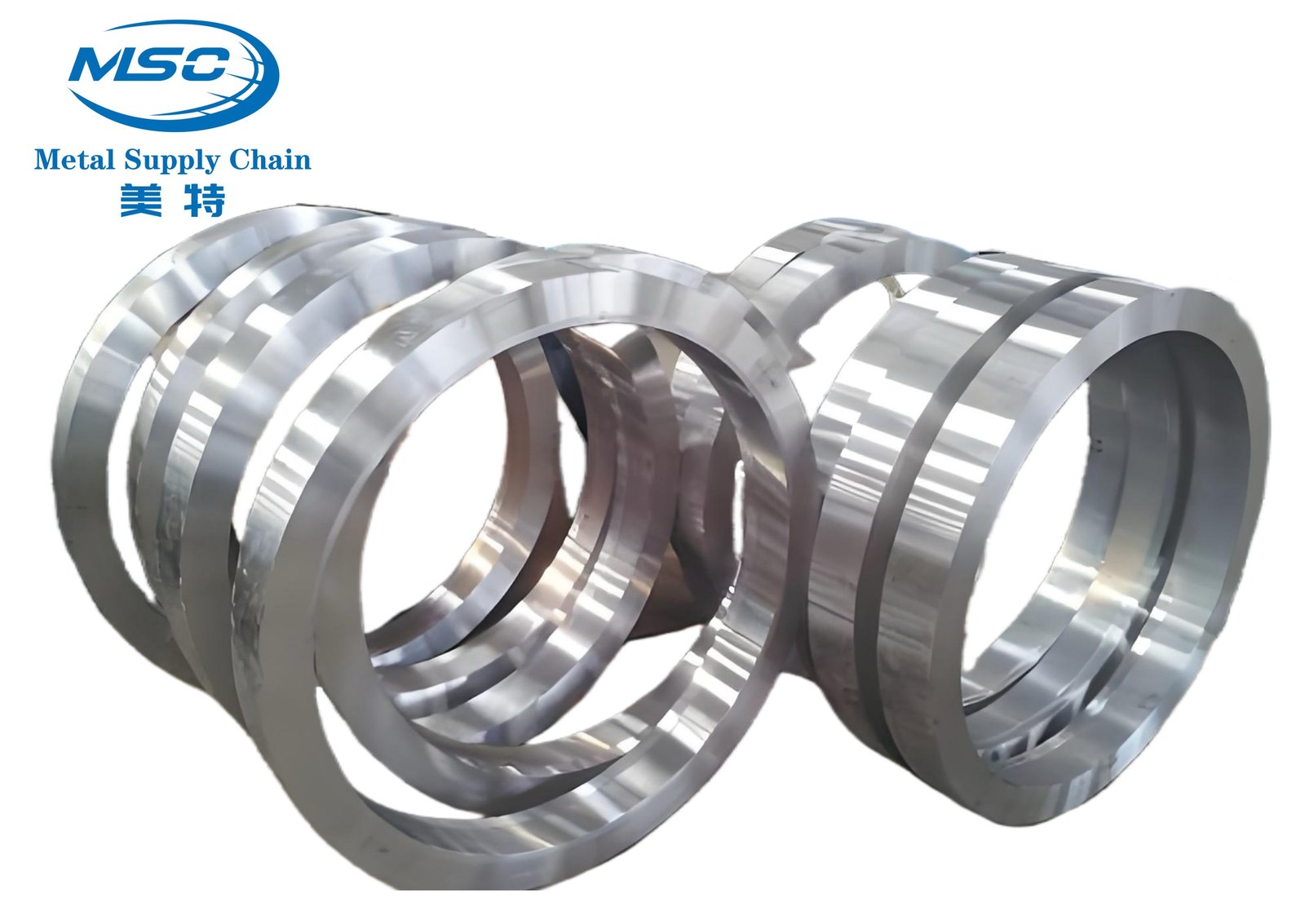

Basic Introduction:

H13 steel is the U.S. standard hot work die steel and electroslag remelting steel, this steel is the world’s commonly used both strength and toughness of hot work die steel, with high hardenability and resistance to thermal cracking. The steel contains high content of carbon and vanadium, good wear resistance, but the toughness is relatively weakened; it has good heat resistance, at higher temperatures can still maintain good strength and hardness, as well as high wear resistance and toughness, and at the same time has excellent comprehensive mechanical properties and high tempering resistance.

Characterizations:

1. Used for making forging molds, hot extrusion molds and precision forging molds with large impact loads.

2. Used for aluminum, copper and its alloy die-casting dies.

3.H13 steel punch after CD carburizing, the service life is increased from 2000~3000 times to 9500~27000 times for CrWMn steel punch. 4.

4. For high temperature thermosetting plastic molds.

Chemical composition:

Heat Treatment:

1. Quenching temperature: H13 mold steel is heated to a temperature of 750-800 ℃, held for a period of time to allow for uniform heating.

2. Quenching hardness: RHC56~58, generally using two tempering process, the first 580 ℃, after a 560 ℃. After more work hardness between HRC47~48.