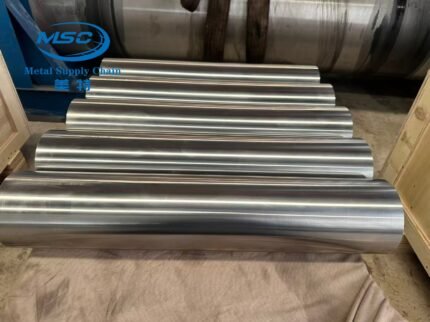

Casing coupling is a short pipe applied in connecting two casing pipes which have threads. The pipe coupling has internal threads machined to match the external thread of the long joints of casing. The two joints of casing pipes are screwed into opposite ends of the casing coupling. Through their strength can be normally made of the same grade of steel as the casing. All casing couplings are manufactured in accordance with API 5CT specification of the latest edition.

♦ The casing couplings thread patterns include short round thread, long round thread and buttress thread.

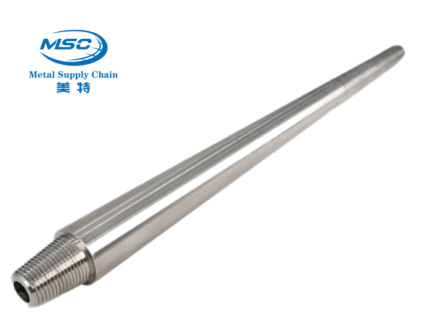

Tubing coupling is a kind of drilling tool available in oil field. Tubing couplings are mainly used in connecting oil pipes. This type of pipe coupling has handled the problem that the existing couplings tend to crack because of stress concentration. The oil pipe ends and the inner wall of the tubing coupling are connected by threads. And the oil pipes and the ends of the tubing coupling have the same type of threads. It is not easy to crack for this type of connection and the connection effect is good. The tubing coupling can avoid the oil well string dropout accident effectively.

Applicable standards:

API 5CT material for body;

API 5B for API threads;

Premium thread per licensor specifications

Main Technical parameters

COUPLING PIPE GRADE IDENTIFICATION BY PAINT COLOR

According to API 5CT standards, Oil casing and Tubing couplings should be painted one by one to distinguish different grades of steel. The color label of the oil casing and Tubing should be sprayed at any end ≥ 600mm, and the color should be painted on the whole outer surface, and then the color ring should be sprayed.