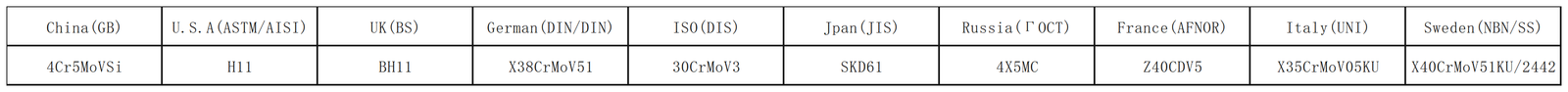

Similar steel grades:

Basic Introduction:

H11 steel is chromium system high strength hot work die steel and high heat resistance and high toughness steel. The chemical composition and metallographic organization of the material after strict control, the organization of fine, the steel toughness and ductility, machinability, excellent polishability, can resist sudden temperature changes and thermal stress fatigue, heat treatment size stability is not easy to deformation, good thermal conductivity, good hardenability, excellent hot hardness.

Characteristics:

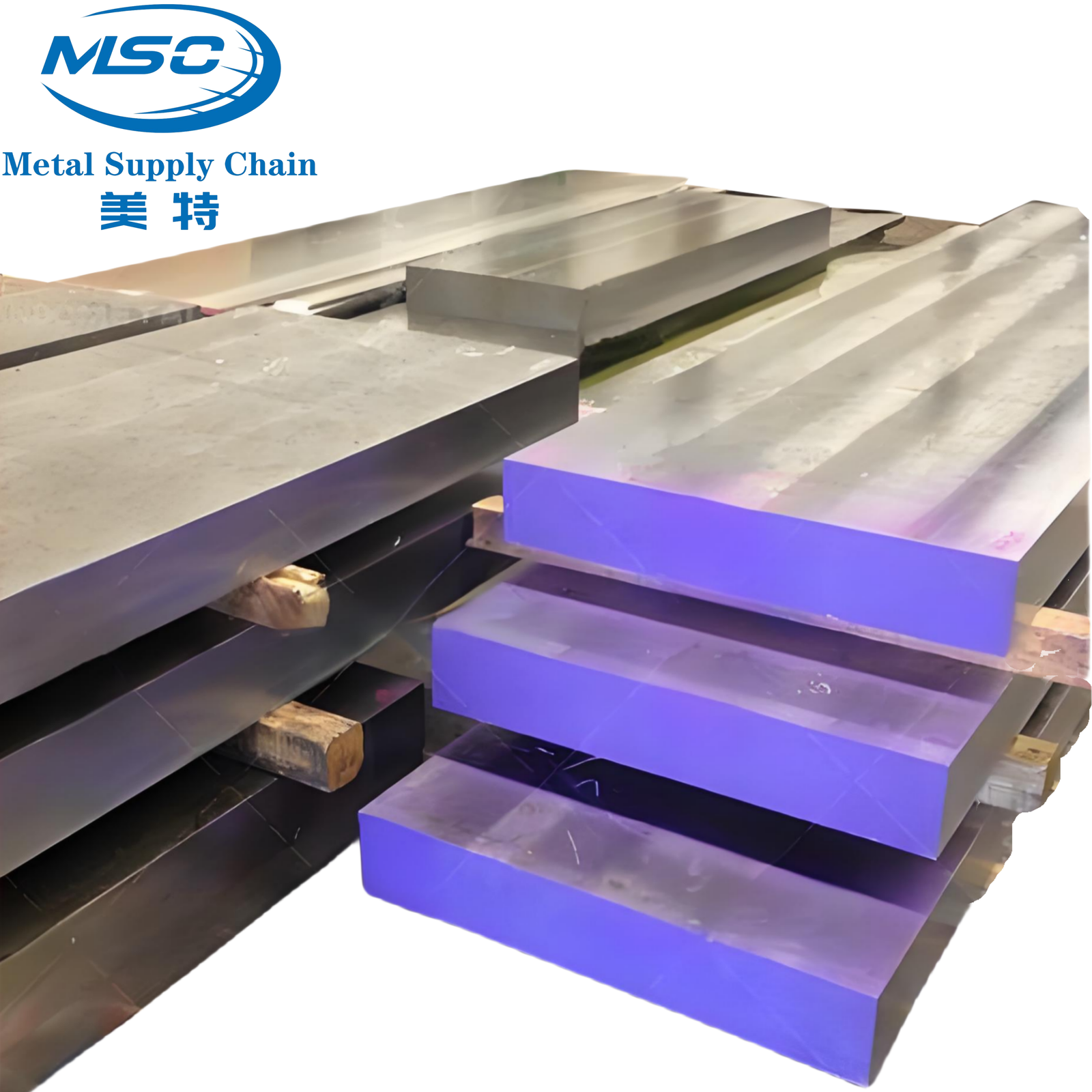

Suitable for high requirements and large-scale aluminum alloy, magnesium alloy die-casting mold. Used in die casting molds (inserts, cores, manifold cones, nitrided ejector pins, nitrided sleeves), extrusion molds (die nuts, die pads, bushings, flow stoppers), aluminum, copper and magnesium hot forming molds, plastic molds, in the cutting, trimming, hot cutting, tightening the ring and wear-resistant components.

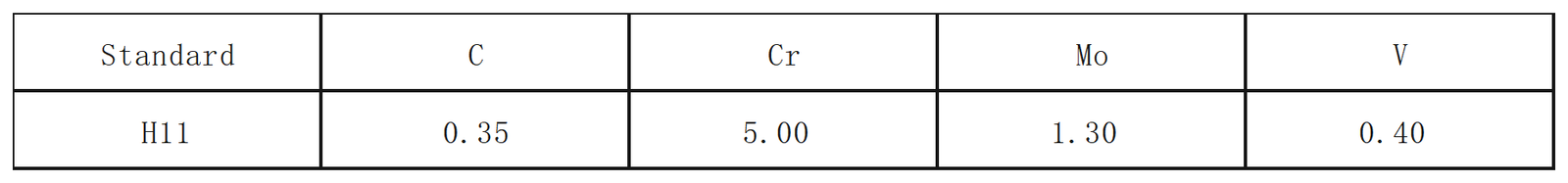

Chemical composition:

Heat treatment:

1. Furnace Atmosphere Control: Maintain a slightly reducing or neutral furnace atmosphere to prevent oxidation of the material surface.

2. Heating speed control: the heating speed should be slow to reduce the thermal stress inside the material.

3. Cooling speed control: control the cooling speed according to the material composition and mechanical property requirements.

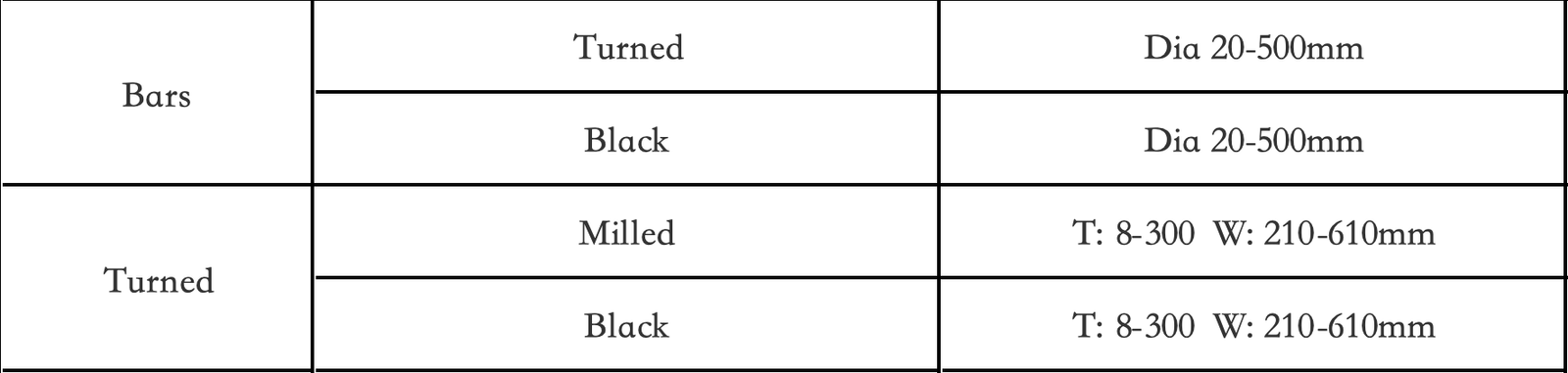

Available sizes: