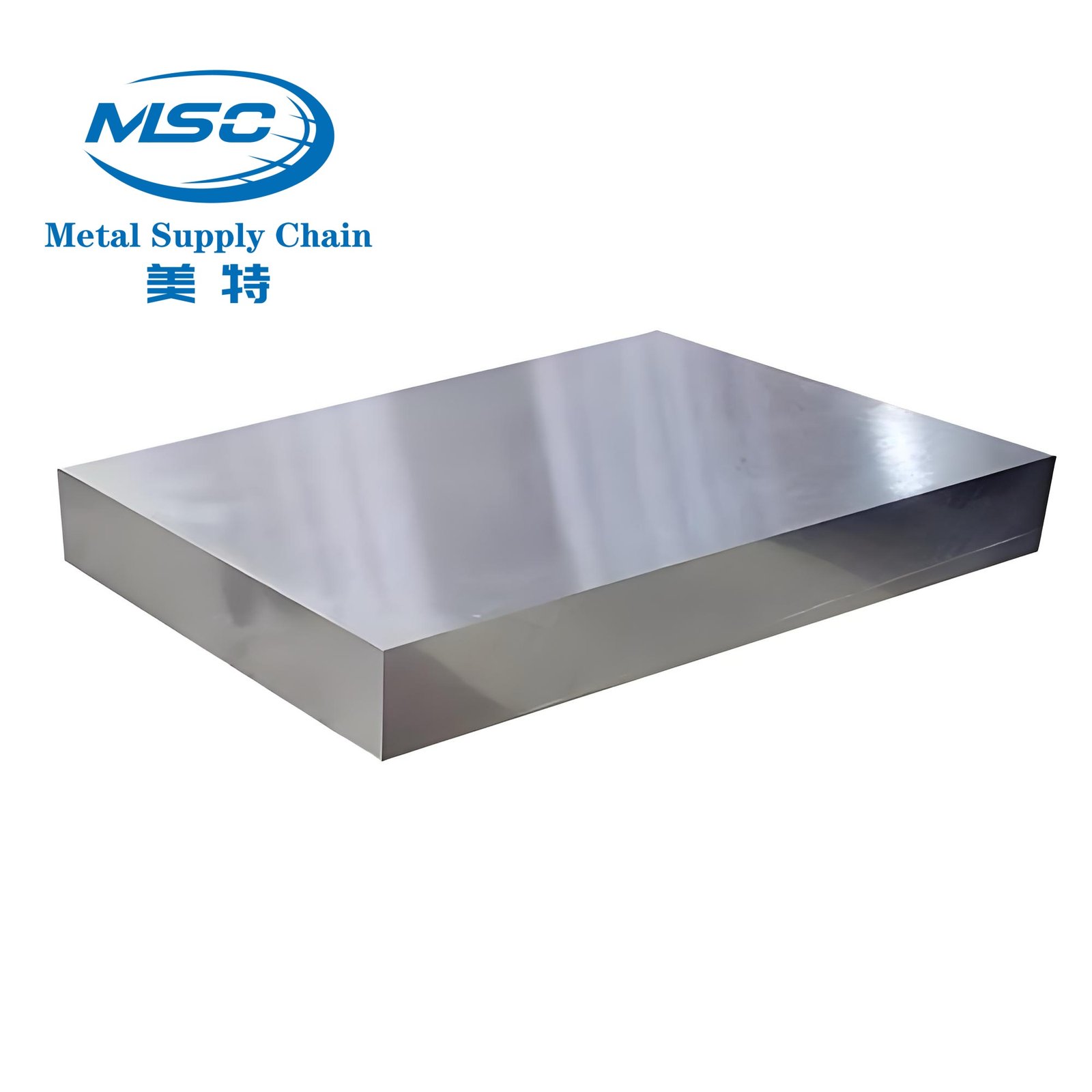

Cr12

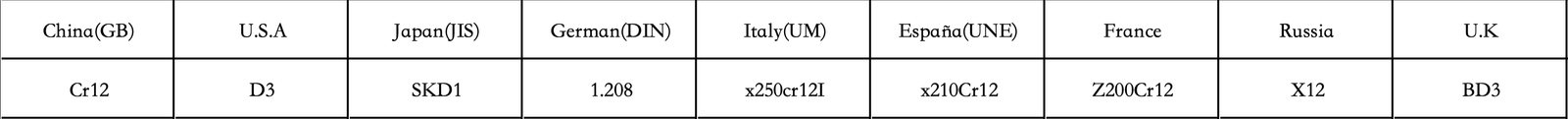

Similar steel grades:

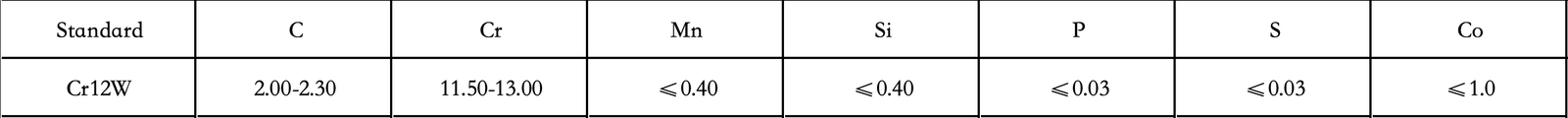

Chemical composition:

Basic Introduction:

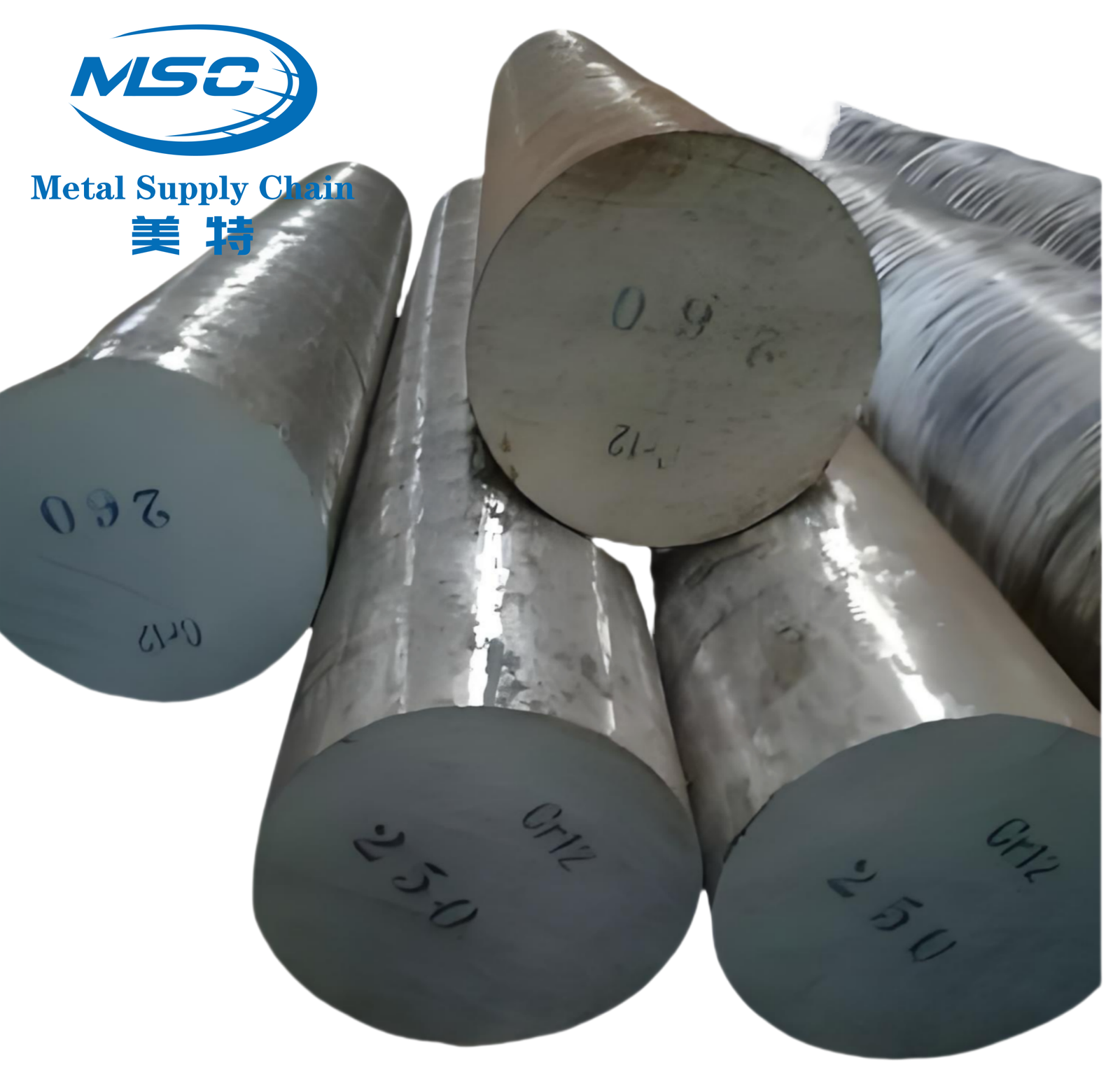

Cr12 is a kind of alloy tool steel, with good hardenability and good wear resistance, mainly used as a small shock load, high wear-resistant cold punching dies and punches, cold cutting scissors, drill bushings, gauges, wire drawing dies, embossing dies, thread rolling plate, stretching die and thread rolling die.

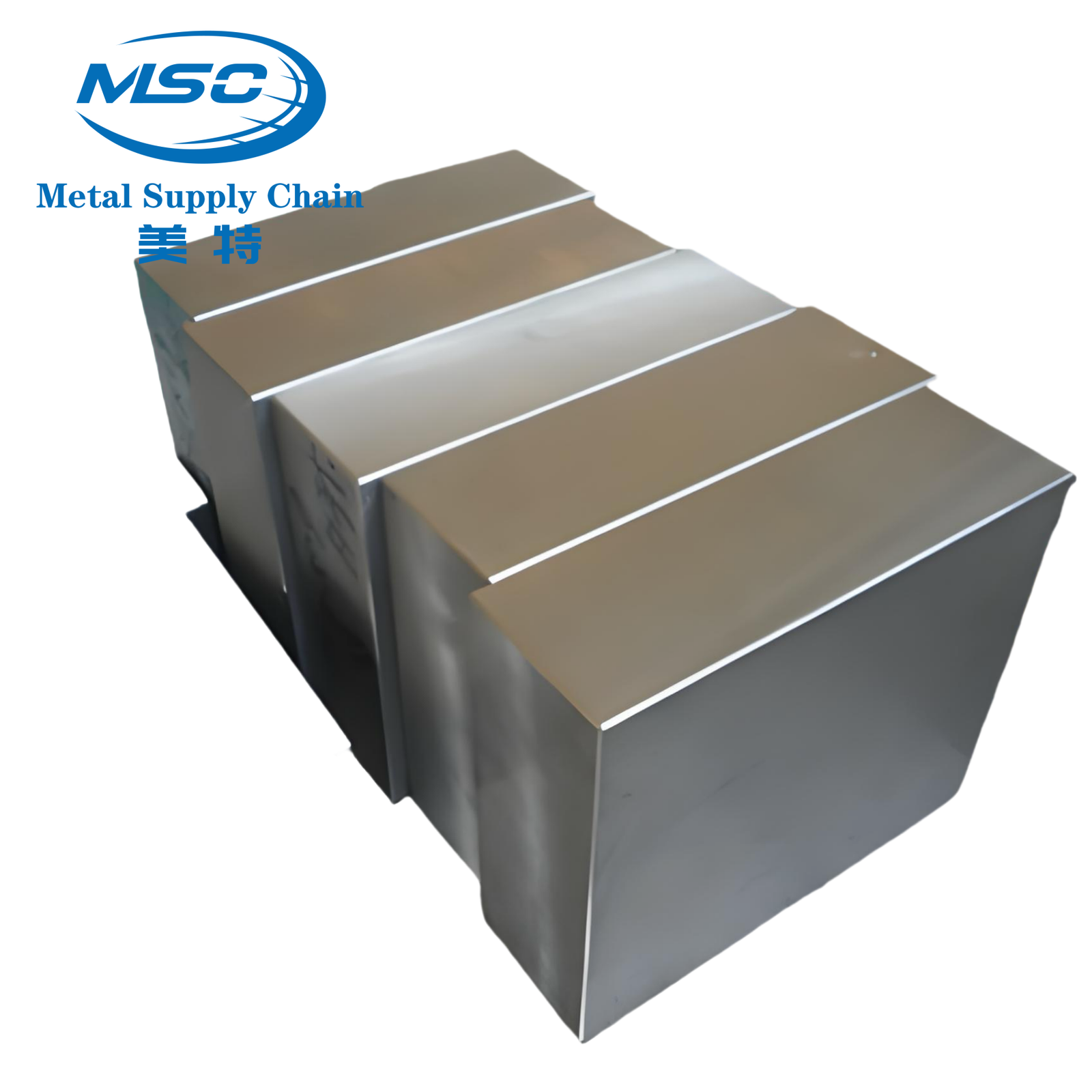

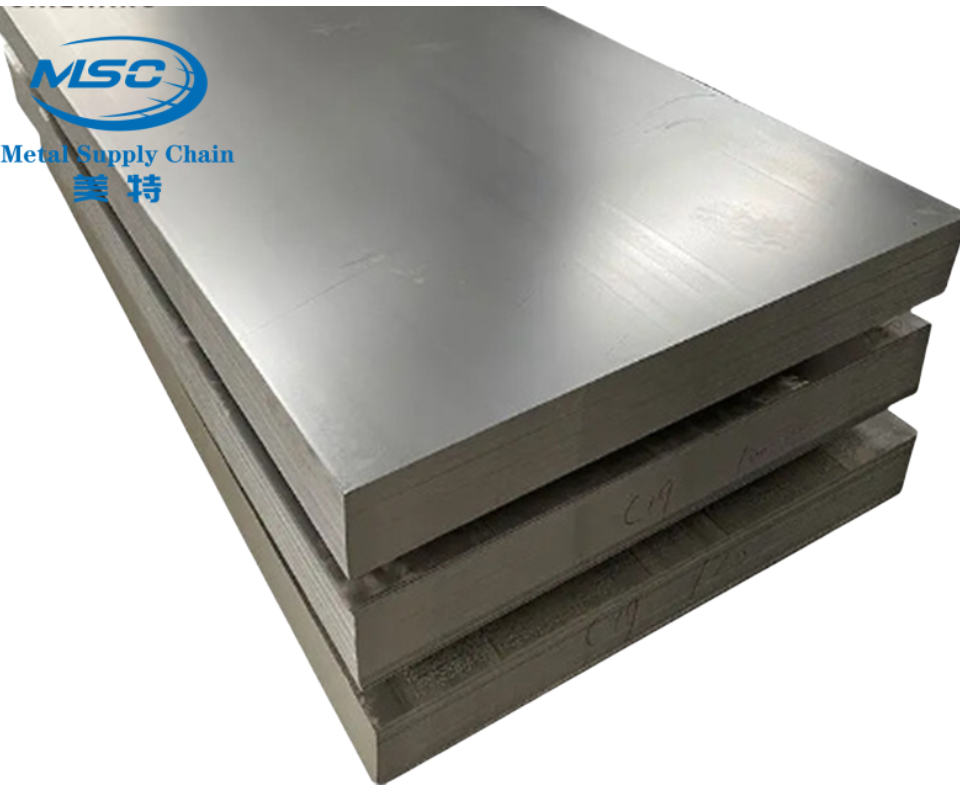

Cr12 mold steel belongs to the high carbon and high chromium austenitic steel, is also widely used in cold work mold steel. The steel has good hardenability, wear resistance, hot workability. Carbide in the steel distribution is good, can be used for the manufacture of complex shapes, working conditions under the heavy variety of cold work molds.Such as cold punches, thread rolling dies, wire drawing dies, material dies, metallurgical powder molds, woodworking cutting tools, cold cutting scissors drilling bushings and gauges and other tools. In our development, after repeated explorations and tests, we have formulated a reasonable smelting process and special ingot die and forging process, so that the material organization to achieve uniformity and consistency, in addition to the standard material processing, bold innovation, the use of double knife chip-cutting new technology, which greatly improves the effectiveness of the shortened cycle, reducing the cost.

Characterizations:

1. Vacuum degassing and refining treatment, pure steel. 2.

2. Ball annealing and softening treatment, good cutting and machining performance.

3. Special addition of vanadium and molybdenum as strengthening elements for excellent wear resistance.

Heat Treatment:

Cr12 quenching 950 ~ 1000 ℃ oil quenching, secondary tempering 550 ℃ high-temperature quenching 1100-1150 ℃, low-temperature quenching 960-1050 ℃, tempering 550-650 ℃, the former has a secondary hardening phenomenon, tempering no less than 2 times, each time 2h, tempering can be air-cooled or oil-cooled, high-temperature quenching is best to carry out 2 times preheating before the quenching, in the high-temperature heating, the need to take protective measures to prevent Oxidation.

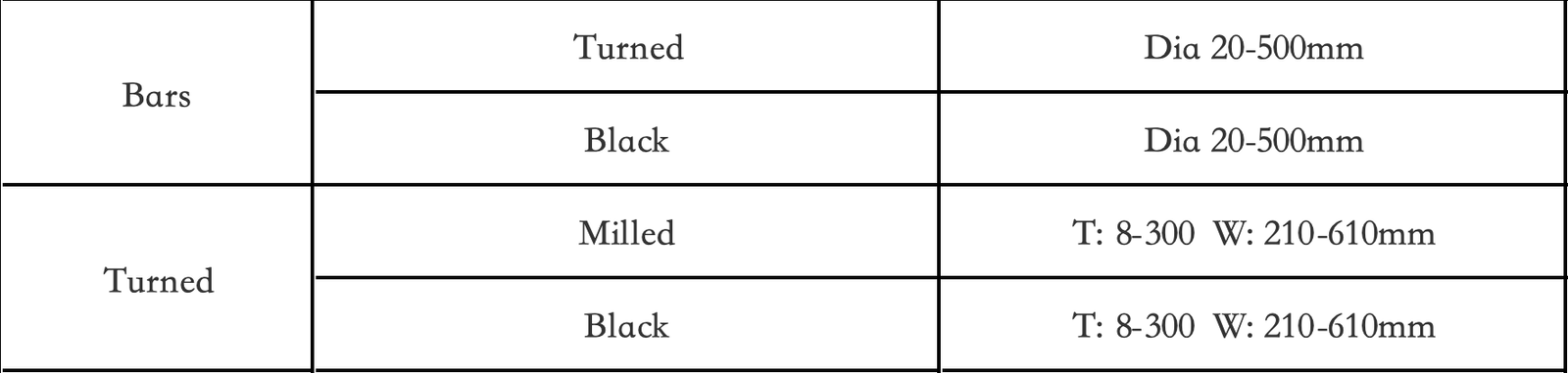

Size available: