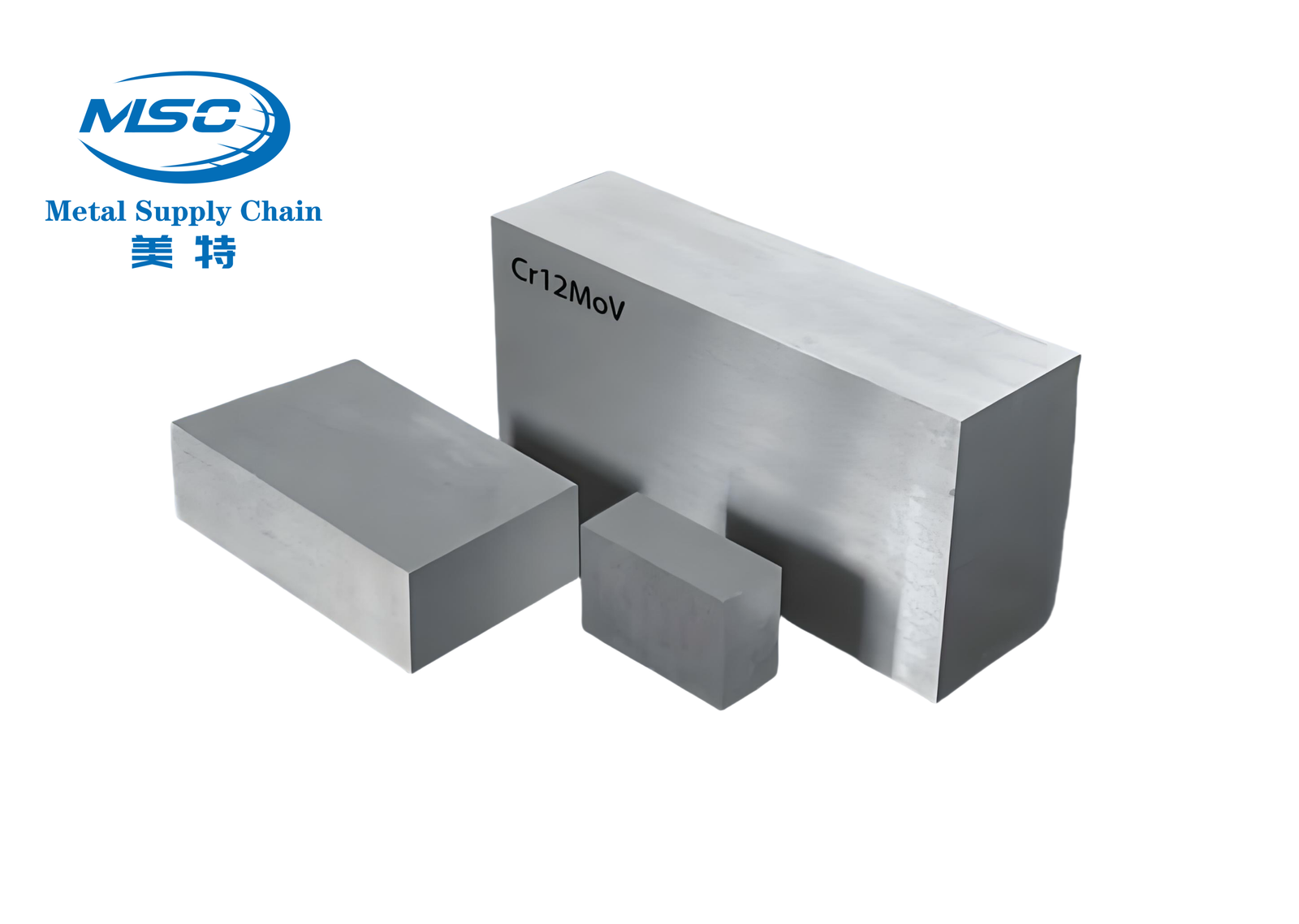

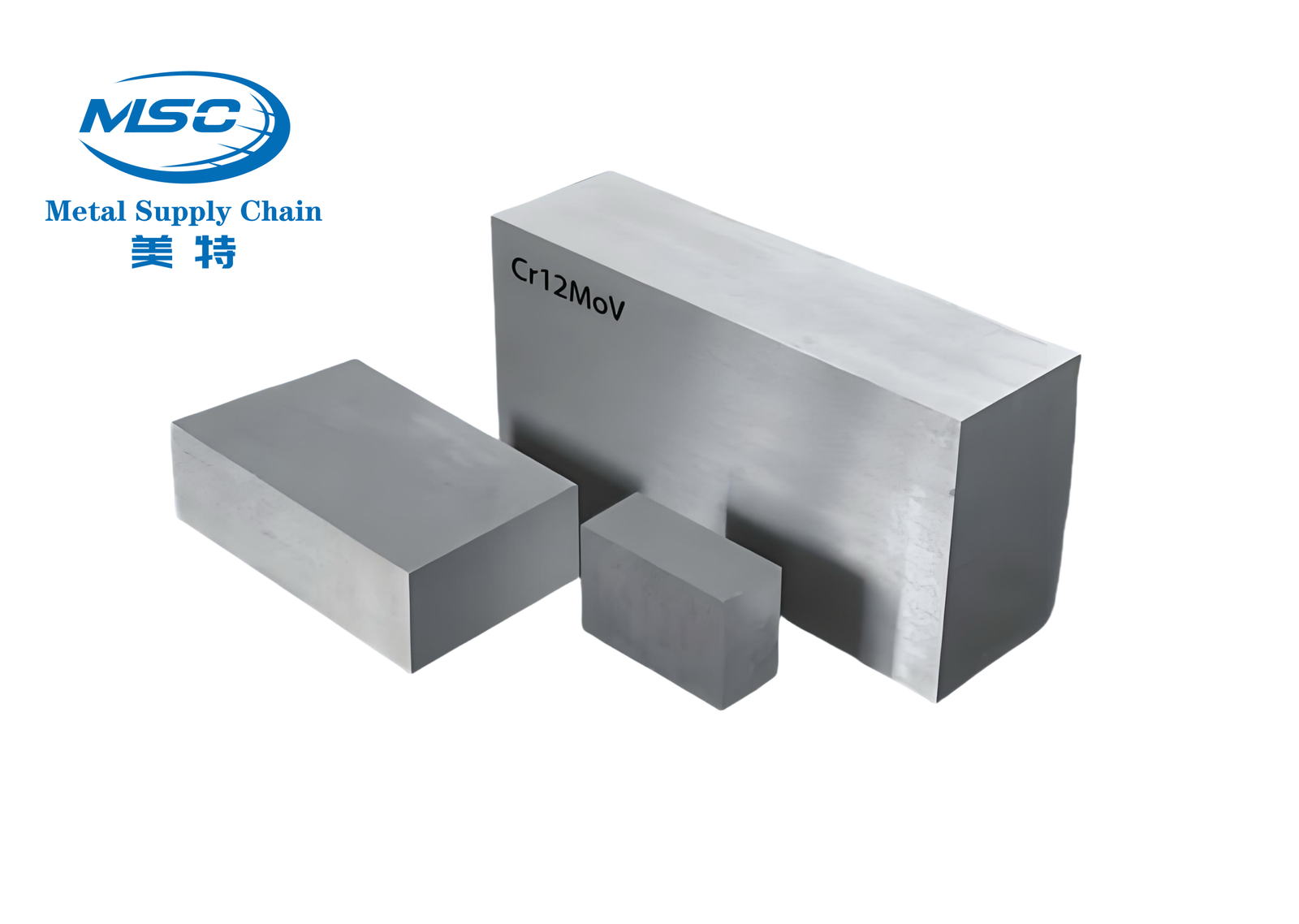

Cr12MoV

Similar steel grades:

Chemical composition:

Basic Introduction:

Cr12MoV die steel hardenability, hardness, strength, toughness after quenching and tempering than CR12 high, the diameter of 300 ~ 400mm below the workpiece can be fully quenched, quenching deformation is small, but poor plasticity at high temperatures.Cr12MoV is more used in the manufacture of cross-section of larger, more complex shapes, heavier workloads of the combined species molds and tools.

Applicable to cold work die steel, steel hardenability, hardness of quenching and tempering, wear resistance, strength are higher than Cr12. Various cold punching dies and tools with complex shapes and heavy working conditions, such as punching concave dies, edge-cutting dies, edge-rolling dies, deep-drawing dies for steel plates, circular saws, standard tools and gauges, thread rolling dies and so on.

Characterizations:

1. The steel can be used to make complex shapes of convex dies, concave dies and inserts for blanking molds with material thickness >3mm. The recommended hardness is 58~62HRC for making convex dies and 60~64HRC for making concave dies.

2. It is used for making high wear-resistant convex and concave dies in blanking molds. Recommended hardness is 60~62HRC for guanidine when making convex dies and 62~64HRC when making concave dies.

3. Used for making concave dies in deep-drawing molds which require high wear resistance, recommended hardness is 62~64HRC.

4. Used for making convex and concave dies and inserts in bending molds which require high wear resistance and complex shapes. Recommended hardness is 60~64HRC when making convex die and 60~64HRC when making concave die

5. Used for making convex and concave dies for cold extrusion of aluminum parts. Recommended hardness is 60~62HRC for making convex die and 62-64HRC for making concave die.

Heat Treatment:

Ordinary quenching, tempering specifications: quenching temperature 1000 ~ 1050 ℃, quenching oil or quenching gas, hardness ≥ 60HRC; tempering temperature 160 ~ 180 ℃, tempering time of 2h, or tempering temperature of 325 ~ 375 ℃, the number of tempering 2 ~ 3 times.

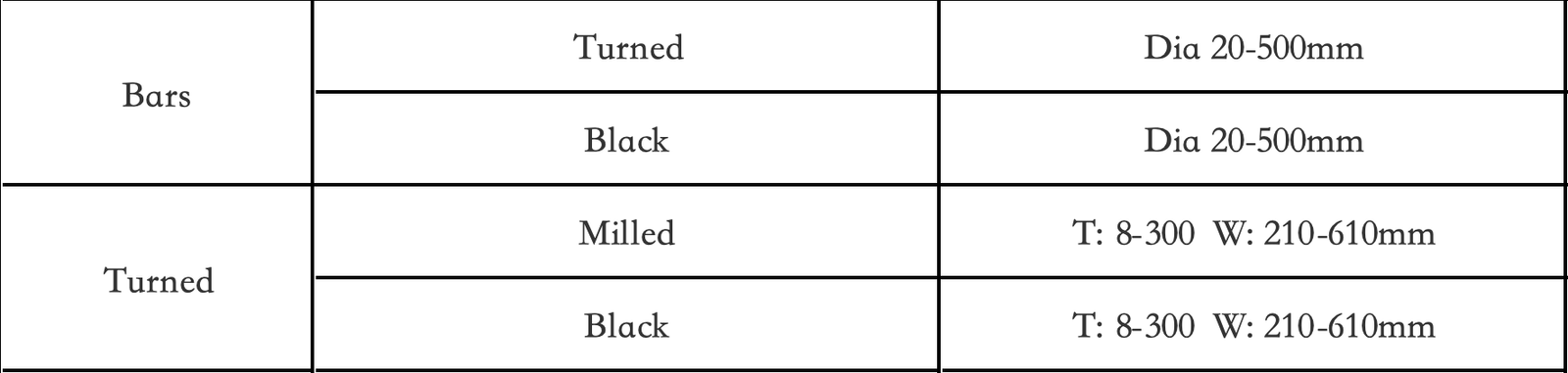

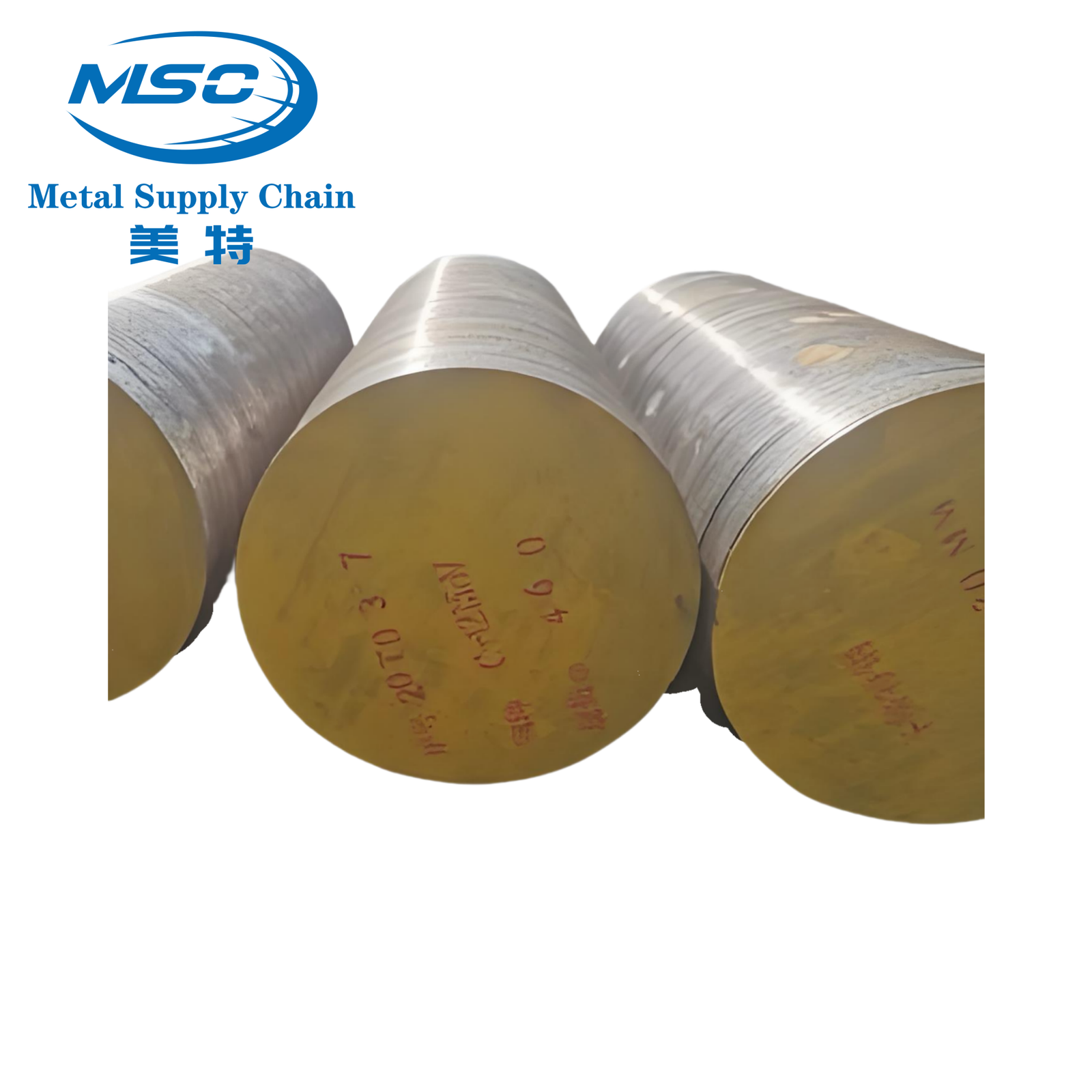

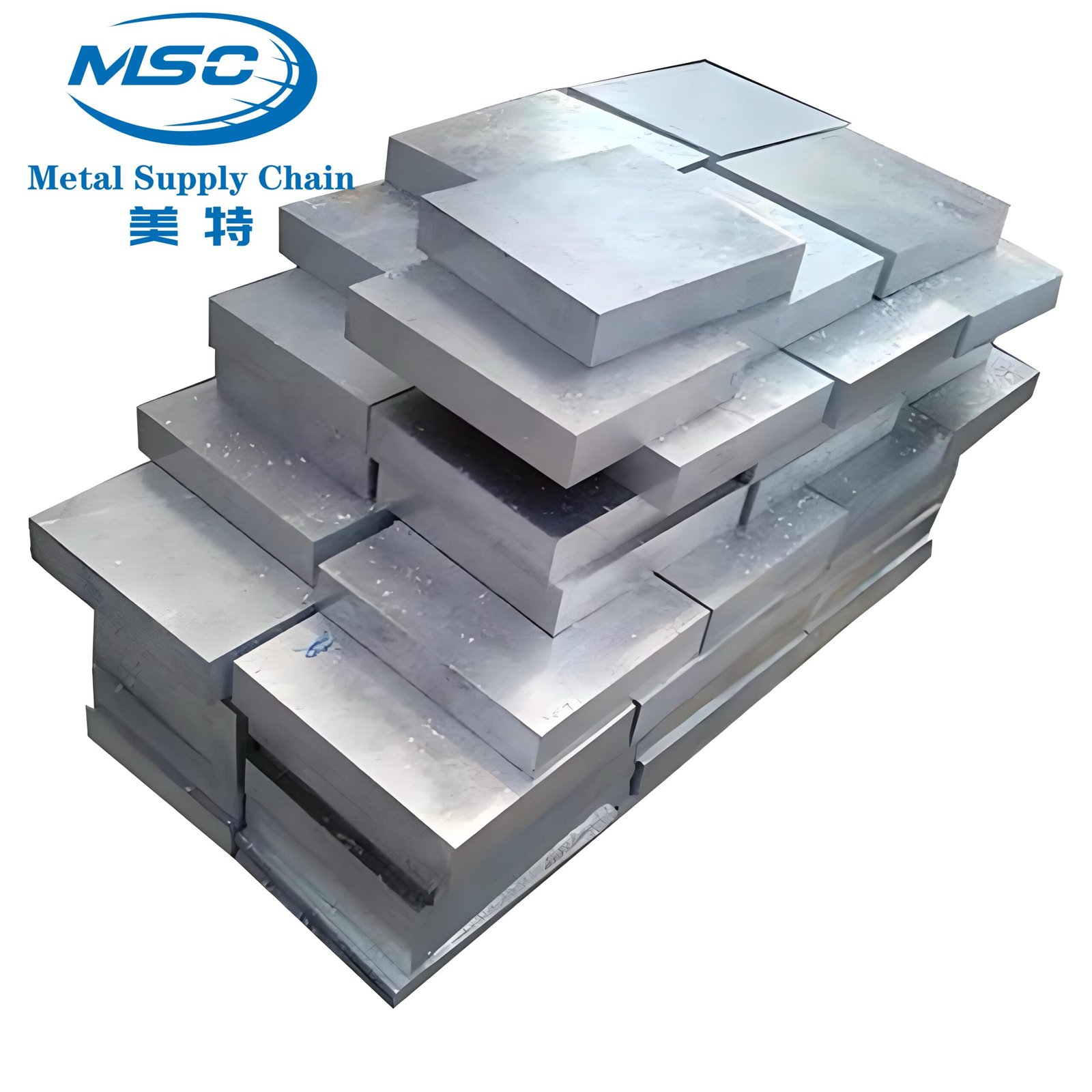

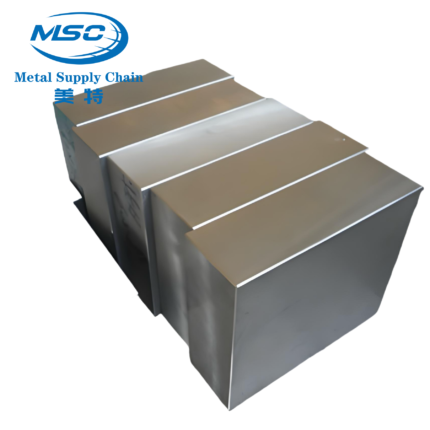

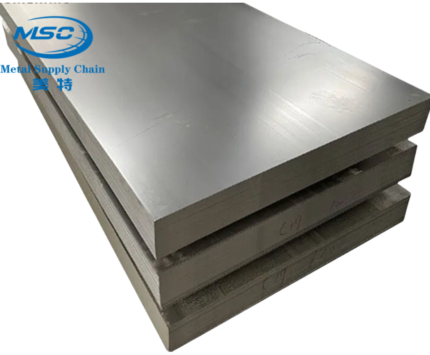

Size available: