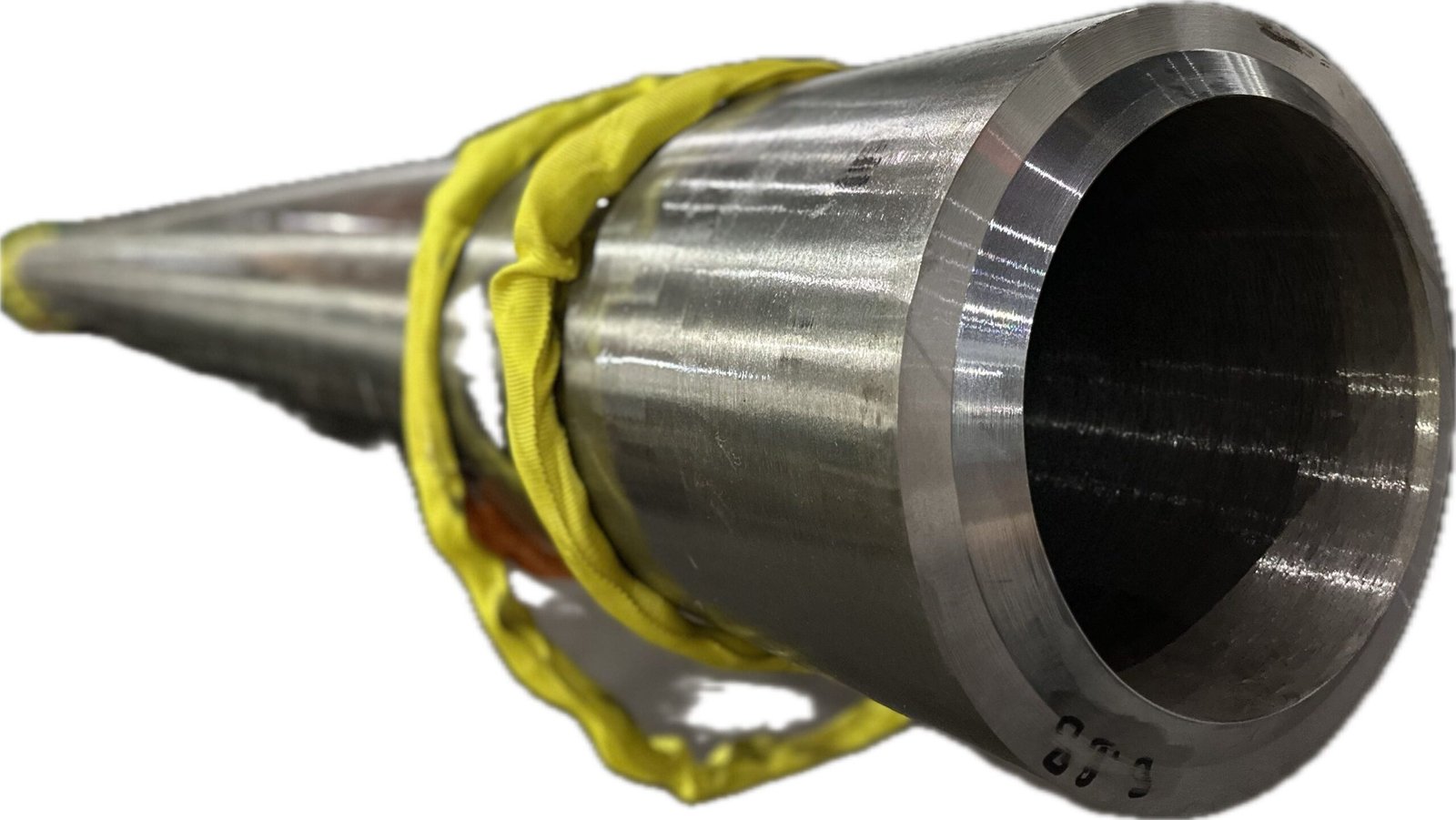

ASTM A335 Grade p91 is also commonly known as ASME SA335 Grade P91 Pipes. These pipes areferitic chrome-moly alloy steel pipes that are majorly used for high-temperature applications. TheUNS designation for this grade P91 is K91560.

The major constituents and Molybdenum (Moly) and Chromium (Chrome). These elements providethe pipe with specific properties such as enhanced corrosion resistance and an overall increase instrength, creep resistance and wear resistance. p91 pipes contain other alloys in minimal quantitiessuch as aluminium, columbium, nickel, nitrogen, titanium, vanadium and zirconium in thecomposition. The pipes are based on the A335 standard but when forged or bored these pipes canalso come under the A369 standard.

Application:

All of these properties make the p91 pipes ideal for use in industrial plants, factories and refinerieswhere these pipes can be used to carry fluids and gasses such as water, oil and steam at extremelyhigh temperatures. Due to their high wear resistance, these pipes last longer and thus are extremelyeconomically viable. These pipes can be used at continuously high temperatures of about 650°C.

Quality Standard:

ASTM A999/ A999M, Standard specification for common requirements for stainless and alloy steel pipe ASTM A92, Hardness test methods for steel materials

E213, Instructions and practice for ultra sonic testing of steel pipe and tube

E309 Eddy-Current Examination methods for steel pipe products

E381, Inspection methods for steel bars, beams, profiles, billets and forgings.

E527, Numbering metals and alloys practices

E570, Instructions for flux leakage examination of ferromagnetic steel pipe products

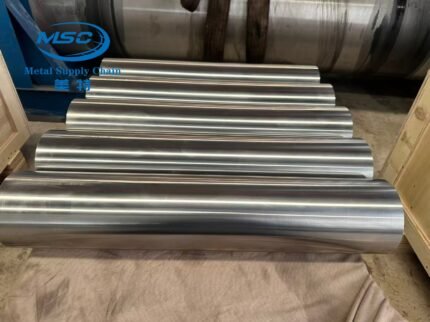

PRODUCT AVAILABILITY:

Standard and Grades: ASTM A335 / ASME SA335 Grade P9, P5, P1, P11, P22, P91

Material types: Chrome Moly Alloy

Manufacturing types: Seamless hot rolled

Sizes: 1/2” to 24”

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Length: 6 meters, 12 meters or customized.

Surface treatment: Polished, Varnished, 3LPE, FBE

Ends: PE (Plain End), BE (Beveled Ends)

Chemical Composition:

A New designation established in accordance with Practice E527 and SAE j1086, Practice forNumbering Metals and Alloys (UNS).

D Applies to both heat and product analyses.

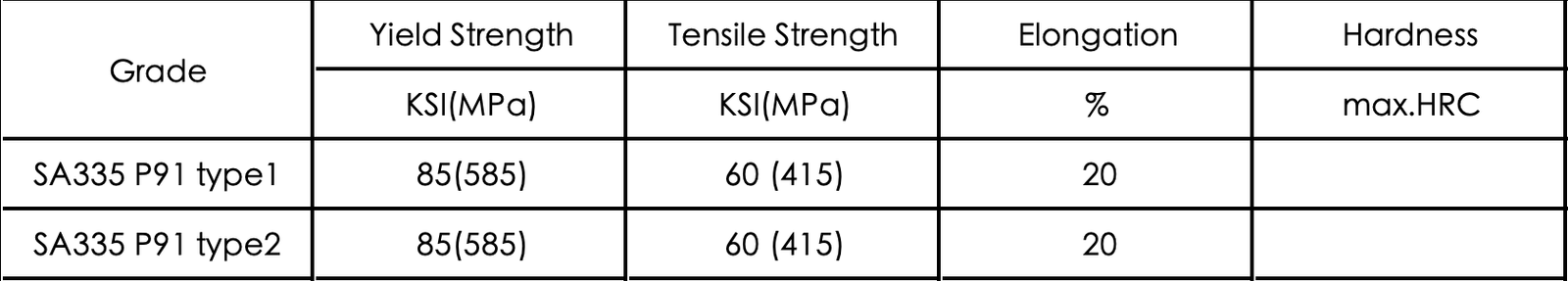

Mechanical properties:

Mechanical Tests Required:

Transverse or Longitudinal Tension Test, Hardness Test, and Flattening or Bend Test

>For material heat treated in a batch-type furnace, tests shall be made on 5 % of the pipe from each treated.

lot. For small lots, at least 1 pipe shall be tested.

>For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to.

constitute 5 % of the lot, but in no case less than 2 pipe.

>Unless otherwise specified, the flattening test or bend test shall be chosen at the manufacturer’s option.