API 5CT L80 13Cr / Super 13Cr offer enhanced mechanical properties and corrosion resistance. The low carbon improves weldability whilst maintaining the martensitic microstructure.Available in bar or tube form, its main application is within the OCTG tubing & casing and downhole completion equipment. When bill of material requirements can be matched against the wide stock of sizes available, considerable cost savings in both raw material supply and manufacturing are achievable against the comparable bar product.

Application

Petroleum and natural gas industries; Corrosio resistand alloy seamless tubes; Casing, tubing, and couplong stock; STC (short round thread casing); LTC (long round thread casing); BTC (buttress thread casing); XL (extreme-line casing); NUE (non-upset tubing); EUE (external upset tubing); IJ (integral joint tubing); Premium Connections

Quality Standard:

API 5CT latest edition at time of manufacture (PSL-1, PSL-2, PSL, 3)

API-5CRA Corrosion Resistant Alloy Seamless Tubes for Casing, Tubing and Coupling Stock

API-5B Threading, Gaging and Thread Inspection of Casing, Tubing and Line Pipe Threads ISO 11960:2004, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

ISO 13680-2000 Petroleum and natural gas industries-Corrosion-resistant alloy seamless tubes

DEP 39.01.20.10-Gen L80 13%Cr casing and tubing (amendments/supplements

DEP 39.01.20.30-Gen Corrosion-resistant alloy seamless tubes

DEP 39.01.20.31-Gen Care and use of casing and tubing (endorsement of ISO 10405)

GOST 632-80 Specification of Casing Pipe and Couplings form THEM

PDVSA EM-18-00-05 Requirements for Casing and Tubing

PRODUCT AVAILABILITY

FORMS: Seamless Pipe, Tubing

OD:MIN OD: 2-7/8” MAX OD: 10-3/4”

Standard & Non-Standard Sizes Available

RANGE:R1, R2, R3

13Cr Series

L80-13Cr; C95-SP13Cr1; C95-SP13Cr2; P110-SP13Cr1; P110-SP13Cr2

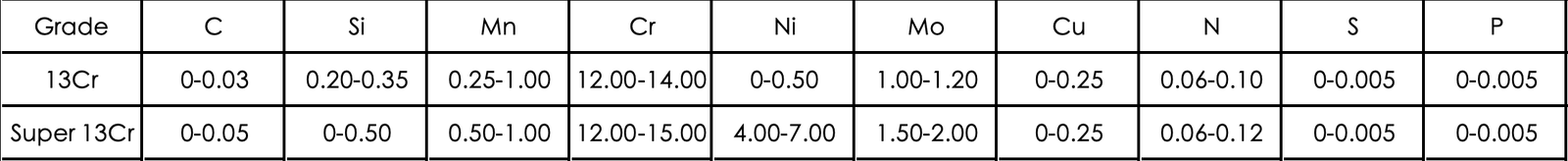

Chemical Composition

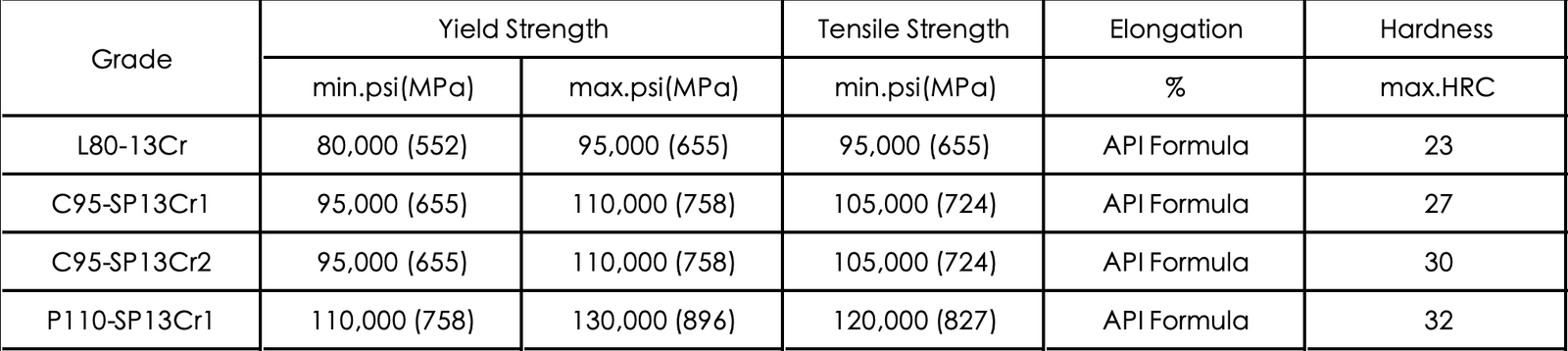

Mechanical Properties

Super 13 Chromes offer improved mechanical properties and increased resistance to the effects of CO2 , H2S, chlorides, pH, and temperatures when compared with standard 13 Chrome. The higher strength and temperature resistance, relative to 13 Chrome L80, allow their use in deeper wells with high pressure and high temperature (HPHT) conditions, as downhole tubular components, packers, and other subsurface equipment. Super 13 Chromes also provide increased resistance to H2S and chlorides relative to Modified 13 Chrome, allowing for use in mild sour environments.